Advertorial

Energy Storage Devices: A Battery Testing overview

Fortsetzung des Artikels von Teil 3

Internal Resistance and OCV Measurements

The performance of a battery and its efficiency during the charge and discharge process can be evaluated in a few different ways, and there are several indicators to look for. The battery internal resistance characterization is one of them. It basically means accurately characterizing the battery’s changes under several charge/discharge current rates, state of charge (SoC), temperature and other aging indicators.

OCV is the voltage measured at the terminals of the battery after enough rest time (sometimes called relaxation), and it is a key measurement for Li-Ion battery cells.

OCV also varies mostly according to battery SoC and, to a lesser extent, according to the temperature. These details can be used to create a battery equivalent model, which is used to design a battery management system (BMS), in addition to assessing the battery specs and condition.

The internal resistance in the battery accounts for the voltage drop across battery’s terminals when a load is connected compared to no-load voltage and can be derived from OCV measurements.

OCV is generally not just a measurement, but a set of measurements. In fact, we call it the OCV characterization of the battery, and we trace an exhaustive analysis derived from a curve on an SoC versus OCV plane.

To trace this curve, you need to bring the battery to specific states of charge. This is typically performed by charging or discharging current in a pulsed way using a smart source/load then waiting for some amount of rest time, and then measuring the open-circuit potential at the electrodes.

A Keithley SMU like the 2461 is the perfect instrument to perform this test. In fact, it can either source or sink the cell current in a controlled way while measuring the cell current and voltage with a four-wire (Kelvin) connection with contact check. All of this is easily automated and controlled by a programmed embedded microprocessor. This specific SMU offers controlled pulsing capabilities for both charging and discharging.

The accuracy of the voltage measurement in OCV is a discriminating factor for the choice of the instrument. In some cases, the typical 6 ½-digit measurement resolution, the thermal stability, and most importantly, the accuracy of an SMU can be considered insufficient.

For this reason, some test setups involve a special digital multimeter, the Keithley DMM7510, that is a standard in Li-Ion battery cell testing. Its low-noise, 32-bit A-D converter allows 7 ½-digit resolution and metrology grade accuracy.

Busbar Weld Impedance Safety Test Workstation in Battery Packs Manufacturing

A battery module is composed of multiple cells that are connected in parallel or series to achieve the desired voltage output. All cells are laser-welded to a busbar—a long conductor that is isolated from the ground and is responsible for carrying high current for the distribution of power from the battery. The VSH-Busbar weld impedance test characterizes the impedance of the weld. Small resistances in the weld can generate enough heat to degrade the batteries and lead to early failures or unsafe operating conditions. By measuring the resistance before testing the battery operation, defective modules can be quickly removed from the line.

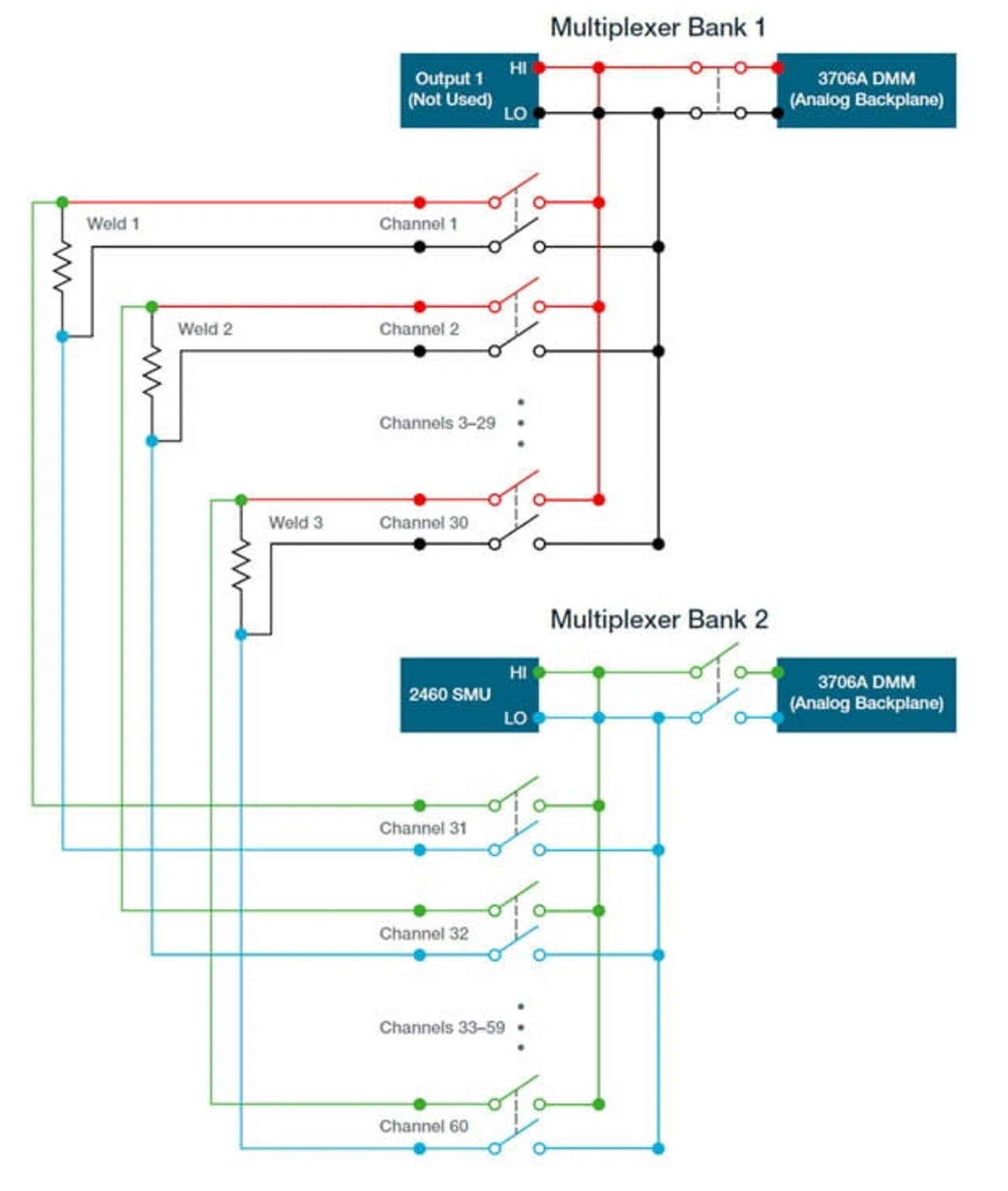

Measuring the impedance of the weld involves sourcing a current across the weld and measuring the voltage to calculate the resistance. Test execution speed and measurement accuracy are the two most important considerations when measuring the weld impedance. This can be done using SMUs like the Keithley models 2460 or 2461 and either the model 3706A System Switch and Multimeter or the model DAQ6510 Data Acquisition and Logging Multimeter System.

The 2460 and 2461 SMUs are capable of sourcing up to 7A for battery systems that require high current. The impedance of the weld can be as small as a few milliohms, so it’s important to use a sensitive enough meter to measure very small voltages. The model 3706A features a 7.5-digit digital multimeter (DMM) and can measure 10s of nanovolts on the 100mV range. Since a battery pack could have close to 80 welds on one busbar, Keithley instruments support mainframes with configurable slots for multi-channel plug-in modules, eliminating the need for rewiring. The process of closing each channel to measure it is obviously automated for speed and efficiency.

ATE Design in Battery EOL Testing

When the battery-operated device is a vehicle, things become quite interesting.

First, you tend to deal with a significantly large number of cells to test, and the test equipment is sophisticated and requires very high reliability. ATE design in this application space needs to support multiple tests on multiple devices. The characterization methodologies also need to be simple and a low-cost alternative to the more advanced and higher-resolution scientific alternatives, which tend to be time-consuming and expensive to set up.

At the cell level, there may be “electrochemical workstations” to set up. But when dealing with modules, the focus is on higher current testing. Finally, the test on complete systems (packs) can involve high currents and high voltages (1000A and 1000V or more are quite common today).

Single cell testers are typically multi-channel systems. What matters here is the voltage and current resolution of the measurement and its stability under varying environmental conditions.

BMS ATEs are designed to accurately monitor cell voltages and temperature, and monitoring the changes in impedance is key.

- Energy Storage Devices: A Battery Testing overview

- Li-Ion Batteries Manufacturing: a quick look into production

- Cell-level Assembly, Stacking, Tab Welding, Filling

- Internal Resistance and OCV Measurements

- Impedance Measurement of Cells