MOST Physical Layer

Glass Fiber Connectivity for Automotive Networks

Fortsetzung des Artikels von Teil 2

Glass fiber and cable concept for automotive application

When calculating the required analogue bandwidth needed for a physical channel using digital on-off-keying data transmission, the rule of thumb gives a factor of 0.7 bit/s/Hz. Calculating a bandwidth of 5 Gbit/s, this fact results in a basic corner frequency of 3.5 GHz for the physical channels low pass filter property. Thus, for a link length of 15 m, the fiber must have a bandwidth-length product of at least 52 MHz·km. Giving some more bandwidth and length, the calculation for a 40 m link at 10 Gbit/s would give a result of 280 MHz·km for the minimum bandwidth length product. Standard available modern high bandwidth performance optical fibers have core diameters of 50 µm and 125 µm cladding. These dimensions require axial alignment tolerances in the range of <5 µm. On the other hand, the fibers are available with bandwidth length products of up to 4,700 MHz·km! In order to ease the necessary alignment precision while maintaining a given coupling efficiency, larger core diameters would be beneficial in order to stay within the tight cost frame the automotive market allows for. But, as a drawback, larger core diameter will reduce the achievable bandwidth capability of the optical fiber.

The minimal bending radius allowed for an all glass fiber (AGF) is directly linked to the lifetime probability. The thicker the fiber diameter, the lower the acceptable minimum bend radius to achieve a specified lifetime for the fiber. With that in mind, TE proposes developing a gradient index type of fiber with a core diameter of 85 µm while maintaining the data communication standard glass cladding diameter of 125 µm. These fibers come with a numerical aperture of 0.275. The bandwidth length product for those fibers at 850 nm is >500 MHz·km. For sufficient lifetime reliability, the bend radius for these 125 µm cladding diameter fibers can go down to 7.5 mm in the long term. In order to withstand the mechanical and chemical requirements in an automotive environment, a proper cable design is needed. One of the main challenges is the pull-strength, as the requirement of 60 N is too high for a 125 µm glass fiber. The forces have to be handled within the cable construction to prevent overload on the fiber. On the other hand, the termination should keep cost efficient.

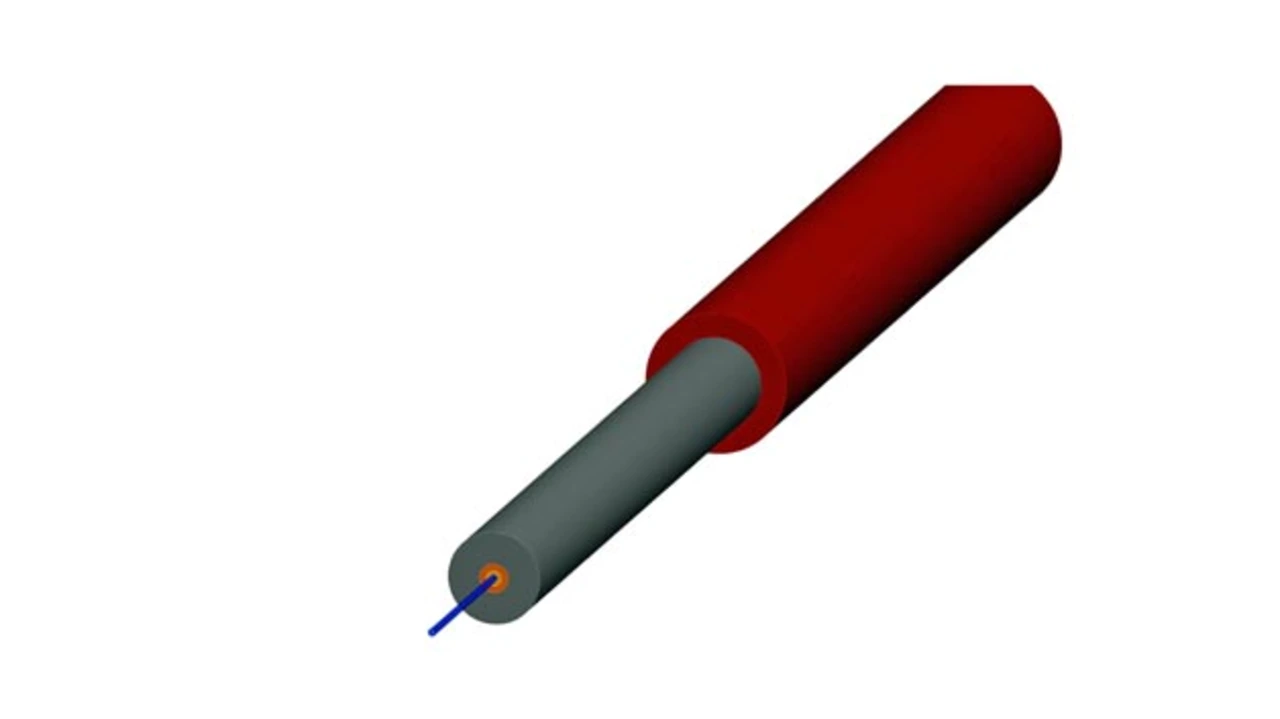

The proposed cable design incorporates several functional layers, as you can see in Figure 1. The pure silica optical fiber has an outer cladding diameter of 125 µm. The inner core has a laser launch optimized graded index profile of 85 µm diameter. As a first protecting layer, an acrylate coating is applied. In order to cushion the sensitive fiber, an inner buffer layer of a softer acrylate is wrapped around it. To give the cable high pull-force durability, an additional buffer layer with embedded strength member is necessary. This buffer layer is designed to be laser weldable in order to ease process automation at the fiber/cable termination. An outer protection layer completes the layer stack of the cable design proposal for color coding and marking.

- Glass Fiber Connectivity for Automotive Networks

- High data rates are possible

- Glass fiber and cable concept for automotive application

- Connector proposal

- The fiber and cable termination process proposal

- Concept discussion: Expanded beam versus physical contact

- Recommendations

- The authors