Micro-supercapacitors

How printed energy storage can enable e-textiles in the future

A new study has shown that micro-supercapacitors can be inkjet-printed onto clothes. This can power electronic textiles and enable a new form of wearables that could support a range of health applications.

Energy storage devices that are ultra-thin, lightweight and flexible, can be inkjet-printed onto clothes to power of electronic textiles (e-textiles) as a new study has shown. Research by Nottingham Trent University (NTU), the University of the West of England (UWE) and University of Exeter shows how high-performance micro-supercapacitors can be used to power e-textiles to support a range of health applications in a sustainable way.

The development allows for the electrodes to be printed onto the fabric of garments to provide power to wearable technologies that are embedded in the clothing while allowing them to remain fully wearable and washable. Supercapacitors store energy electrochemically and have advantages over ordinary batteries, such as being faster to charge and discharge, having longer lifespans and being more cost-effective.

Printed energy storage

The study – published in Advanced Functional Materials journal – shows how inkjet printing ultra-thin layers of two-dimensional materials including graphene, molybdenum disulfide (MoS2) and hexagonal boron nitride (h-BN) is the most accurate way to form a layered material, known as a heterostructure, to create a micro-supercapacitor. Two-dimensional materials are materials that are so thin that they consist of only a single layer of atoms and have unique properties due to their thinness.

»E-textiles are widely considered to be a promising healthcare solution which can help allow for the unobtrusive monitoring of human health to support diagnoses at the point of care,« said Professor Nazmul Karim, of the Nottingham School of Art & Design at NTU, who supervised the study. »But the lack of thin and flexible power supplies has until now hindered the practical adoption of such products, so we wanted to develop ways to enable textile-based micro-energy storage devices to provide the energy that is needed. This research could open a new era in high-performance textile-based micro-supercapacitors which will power the future wearable e-textiles for personalised health care.«

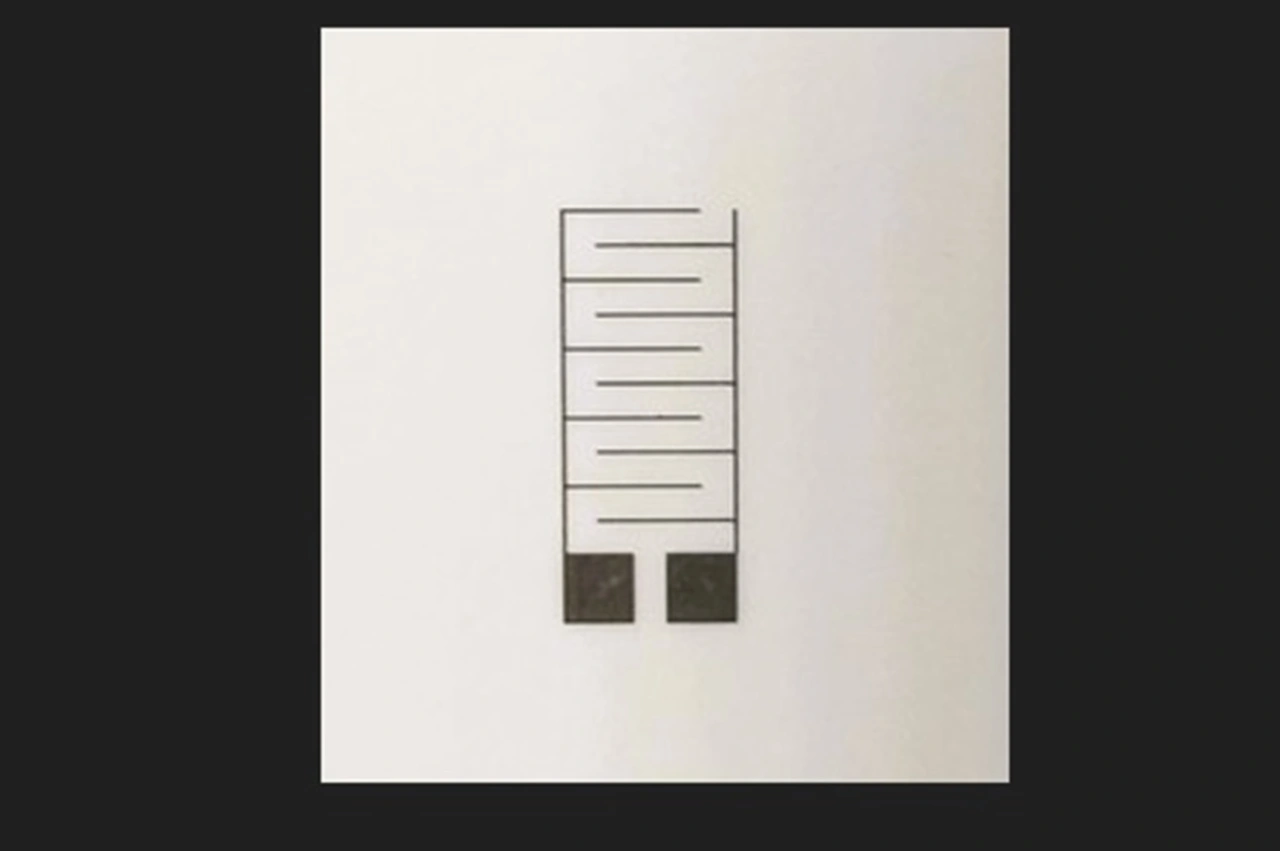

The study shows that inkjet printing is the ideal, high-precision method of creating these heterostructures as it allows for materials to be deposited the most precisely on substrate materials such as textiles. The researchers used graphene as a conductor, MoS2 as a semiconductor, and h-BN as an insulator. The conductive graphene layers were printed on the top and bottom of the heterostructure, while the semiconductor (MoS2) and insulator (h-BN) were sandwiched in the middle.

»We have found that inkjet printing offers the possibility of producing high-quality prints with sharp details, making it an ideal choice for a wide array of printing applications,« said Rashedul Islam, who completed a PhD at the Centre for Print Research (CFPR) at UWE Bristol, and who now works as an assistant professor at Bangladesh University of Textiles (BUTEX) in Dhaka, Bangladesh. »Incorporating MoS2 or h-BN between graphene layers, according to our study, significantly improved the micro-supercapacitor’s performance as the combination of materials enables the devices to act as hybrid supercapacitors. The study highlights the potential of these inkjet-printed heterostructure micro-supercapacitors as a viable power source for e-textiles, paving the way for advancements in personalized healthcare technology.«