Diagnostic Pill Detects Diseases

World's Smallest Impedance Spectroscope to Swallow

Simply pop a pill to identify a defect - as small as a piece of candy, the waterproof IoMT sensor can reliably measure the properties of liquids even in the body. This can help to identify diseases.

If patients complain of pain in the abdomen, there is usually no way around an elaborate and usually unpleasant gastroscopy or colonoscopy. In such cases, electrochemical impedance spectroscopy can provide relief. Researchers at Fraunhofer IZM in cooperation with Micro Systems Technologies (MST) and Sensry GmbH have developed a diagnostic pill that detects the causes of disease in humans inside the body.

Electrochemical impedance spectroscopy

Impedance analysis is used to determine the properties of an object or liquid. Different frequencies are sent from one electrode through the object to another electrode. The resulting spectrum shows a characteristic fingerprint of the medium. If the spectrum changes, it may indicate corrosion or a disease. Until now, the devices for this method were too large and not mobile enough.

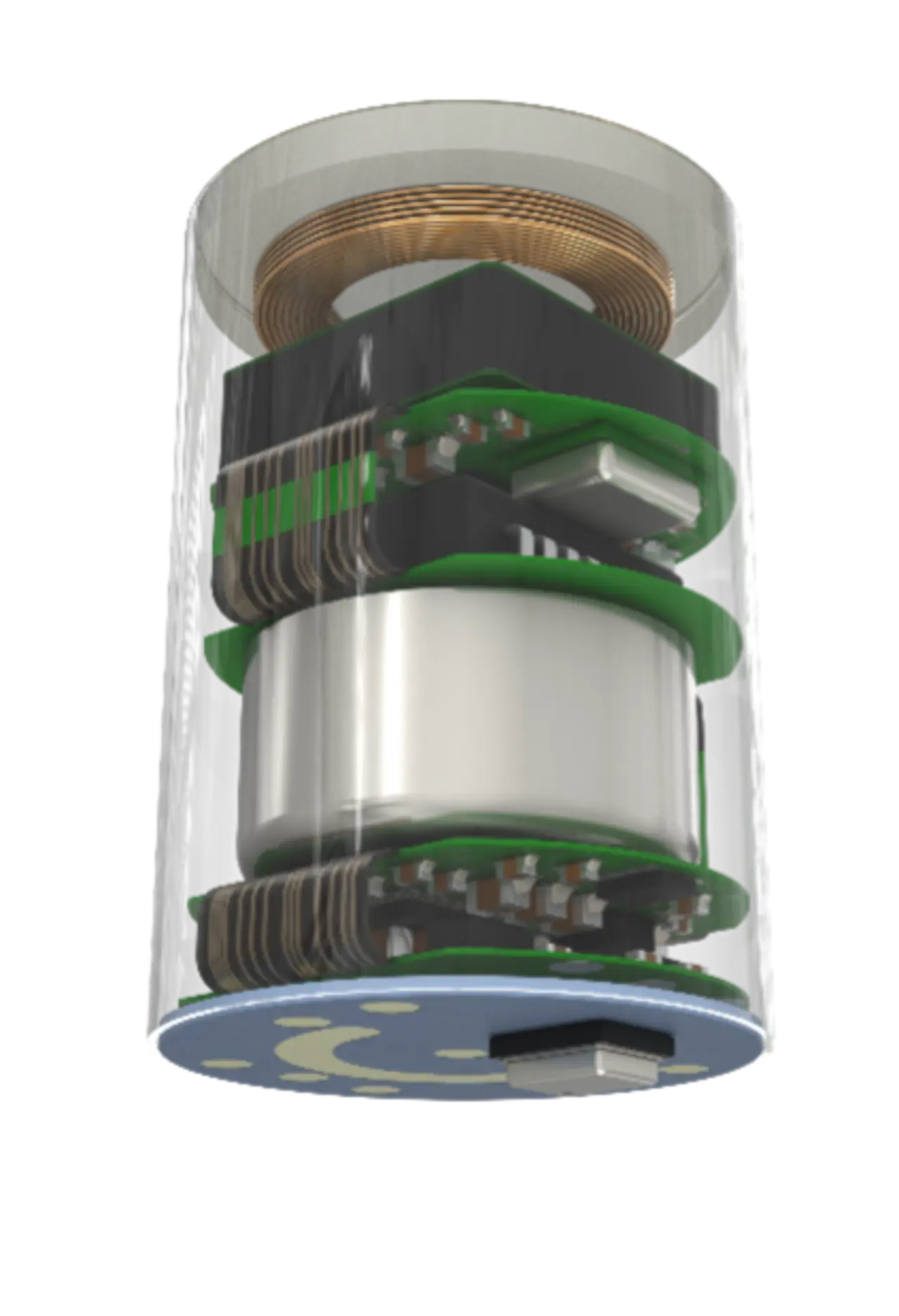

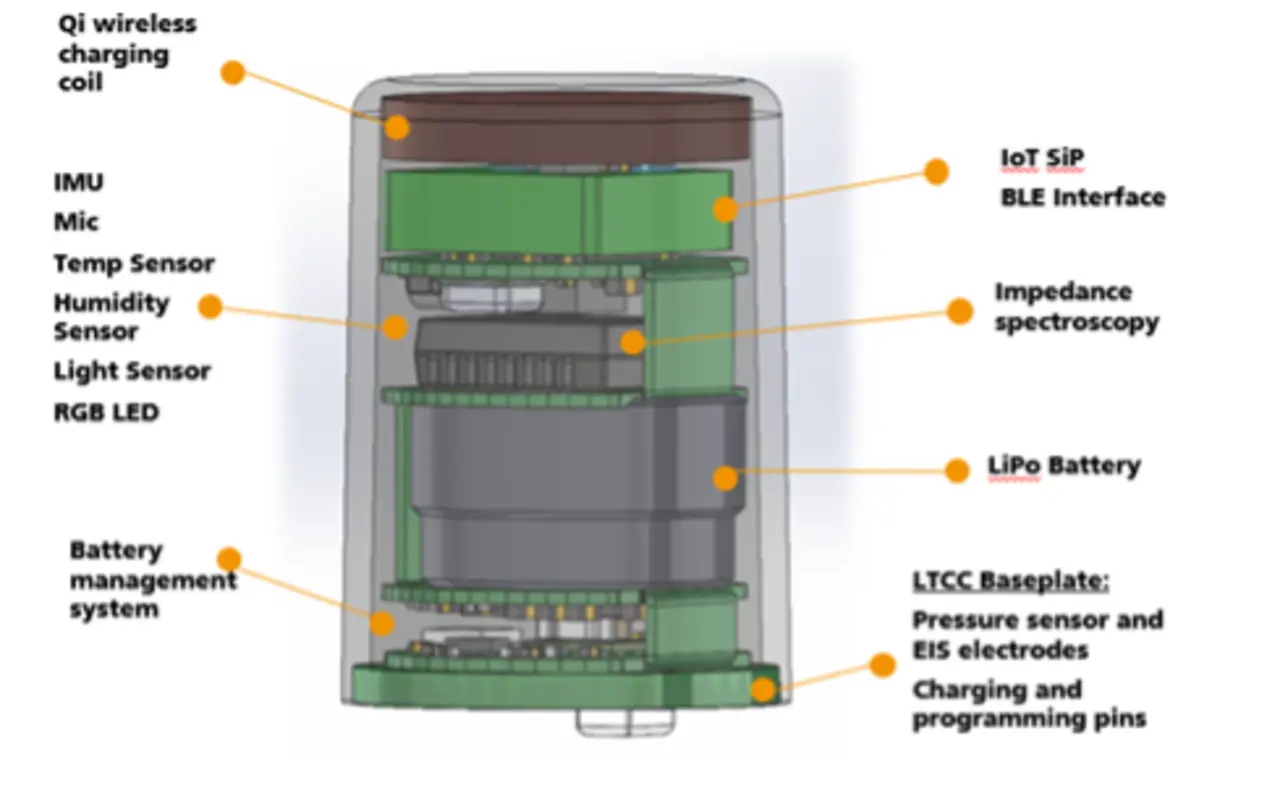

The new diagnostic pill is a compact and modular IoT sensor that can measure impedances and transmit them wirelessly. Consequently, it is not only waterproof, but also biomedically compatible.

Tiny IoMT sensor spies inside the body

The sensor is made of a biocompatible polymer and combines the two necessary electrodes with numerous components for analyzing environmental properties, including six sensors for measuring a wide variety of data, in an area measuring just 11 by 16 square millimeters. In addition to temperature, pressure and humidity, the small medical system can also record its own acceleration behavior, rotation or ambient noise. Light and colors can be determined by an integrated light sensor.

In case of a suspected disease in the digestive tract, the sensor can be swallowed and then flows through the whole system. Wirelessly, accurate data about the condition inside the body is transmitted in real time to a specially developed software with web interface for PC and smartphone. If a location is reached where the pressure or fluid spectrum deviates from the norm, this is an indication that the cause of the problem has been successfully localized. For easier classification of the collected data, the spectra of some liquids are already stored in the software.

Electronics as thin as a hair

In the production of the sensor, the strong miniaturization of the components posed a major challenge. In particular, reducing the coil diameter to 10 millimeters for wireless charging was a hurdle. However, a sophisticated system design made it possible to overcome this challenge. At the start of the project, Sensry GmbH provided its circuit diagrams and Kalisto firmware as the basis for developing the sensor.

To accommodate a total of over 70 passive and active components on a flexible and biocompatible printed circuit board, it was designed from a liquid crystal polymer and manufactured by Dyconex in four layers. Yet it is just 175 micrometers thin, barely thicker than a human hair. A system-in-package was fabricated on a six-layer interposer and forms the core of the sensor, as this is where the IoMT system is united. For wireless charging, the capsule does not even need to be opened thanks to a built-in induction coil and can be charged wirelessly via Qi technology.

Wireless charging and miniature design

Wireless charging and Via a docking station for calibrating and programming the sensor, however, a classic DC charging process is also possible. To prevent the very small components from getting too hot during operation, the sensor is also filled with an epoxy resin that isolates the components from each other and dissipates heat to the outside. At the bottom end, it terminates with a 0.5 millimeter thin four-layer ceramic plate, which was manufactured in the MST Group, and on which the electrodes for impedance spectroscopy are mounted in addition to the pressure sensor. As a trade show demonstrator, the IoT sensor shows how intelligent system design and semiconductor packaging can greatly miniaturize electronics without losing functionality. (uh)