Comau is increasingly diversifying

"Wearable Robotics is a Technology of the Future"

Formerly known mainly for classic industrial robots, Stellantis subsidiary Comau, based in Grugliasco near Turin, now also offers cobots and exoskeletons in addition to a wide range of advanced automation products and solutions, and has established itself in industries outside automotive.

Pietro Gorlier, CEO of Comau, provides more information and explains the current trends in robotics.

Markt&Technik: How is your company's product portfolio currently developing for applications inside and outside the automotive industry?

Pietro Gorlier: We have been in the automotive industry for 50 years and now offer robotics and automation solutions for various industries. Our robot-independent bin picking solution "MI.RA/Picker", for example, is intended for production and logistics across all industries; it is based on two laser sensors and a 3D camera. In our portfolio we also have solutions for mobile welding, developed for unstructured environments, such as construction and shipbuilding. In addition, in the hydrogen field, we are developing automation solutions to produce fuel cells and electrolysers as well as innovative technologies able to provide a 360° E-Mobility strategy, including the dismantling and reuse of batteries. When new opportunities emerge, we will evaluate them. It is no coincidence that we have established a separate business unit for non-automotive.

In our experience, automation in non-automotive applications is usually not linear. So, the challenge is to bring automation into unstructured environments.

Which developments relevant to robotics do you currently see in the automotive industry?

In the automotive industry we see a strong transformation towards e-mobility. The e-mobility market is very different from the classic market for vehicles with combustion engines and requires a high development speed because it is catching up quickly. At the moment, 30 percent of the investments made in the automotive industry are going into e-mobility; in a few years it will be 50 percent.

In general, however, we still see a great and growing need for robotics solutions in the automotive industry. It is the most automated industrial sector, ten times more automated than the second-placed sector. Those who have competencies in the automotive industry can quickly acquire competencies in other industries, and this is exactly our case.

What are the main technical trends in robotics at the moment?

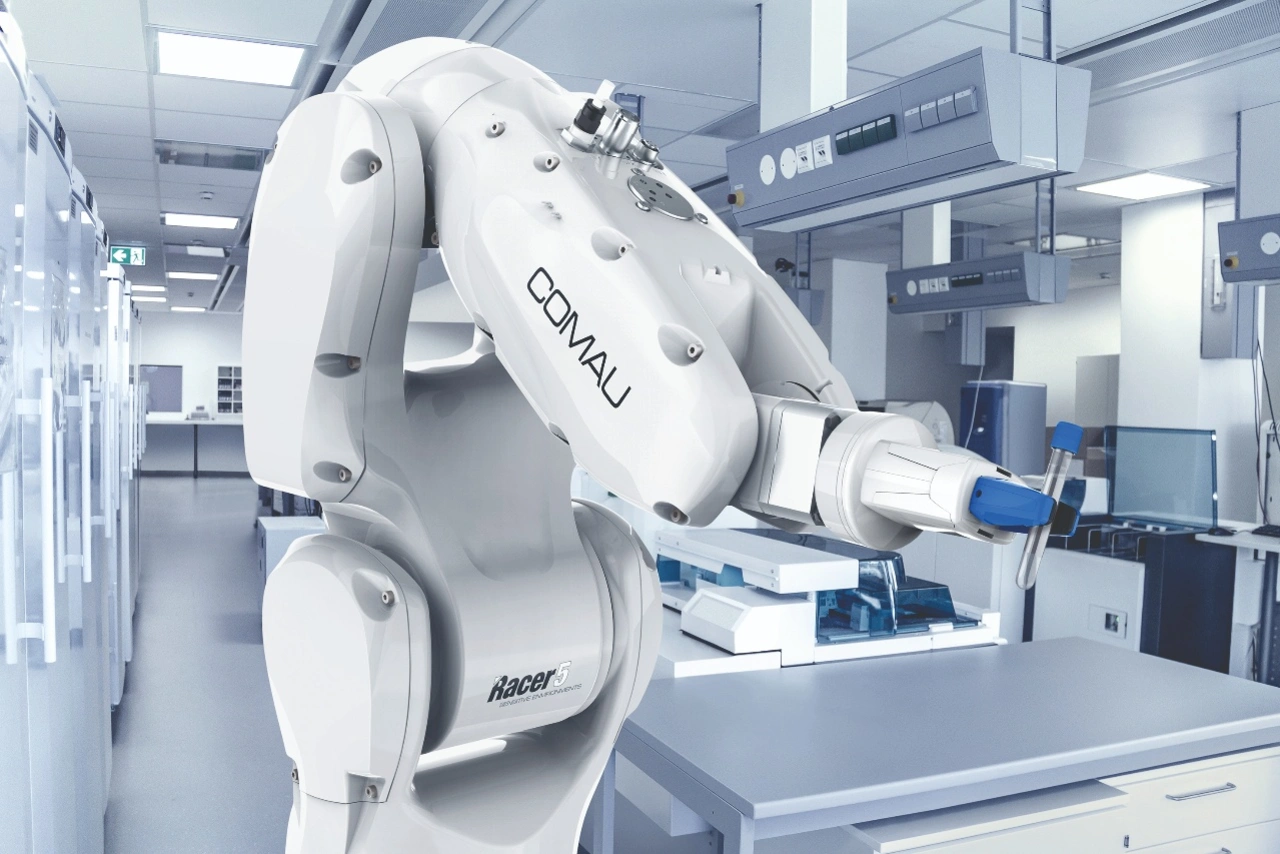

The main trends are flexibility, collaboration, speed and scalability. It is becoming increasingly important to be able to change or switch applications quickly. The demand for collaborative lightweight robots is growing. But their users have to make a compromise: Without enclosure or even collaborative means less speed, so the speed of the overall process decreases. In this respect, cobots will never completely replace classic industrial robots. However, we have solved the dilemma with our cobot "Racer5": The cobot can automatically switch from the speed of a classic industrial robot to collaborative speed when a human operator enters its working area. To be able to perceive the operator, it uses a laser scanner as a sensor.

In your opinion, is there a need or demand for cobots that travel from application to application on AGVs in factory halls and perform specific tasks there?

Yes, definitely. We are currently developing a special solution for our cobot "Racer5". Cobot and AGV then work via the same control system.

We see a growing demand for mobile manipulators (with both collaborative or traditional arms) of this type of applications, even if most of the use cases are still in the development phase. Especially the logistic automation market is pushing for this to simplify handling of goods. Another drivers are the area where traditional stationary robotics is not suitable, such as automation in unstructured environments and outdoor applications.

Which market share do cobots have now compared to classic industrial robots?

At the moment, the share of classic industrial robots is 87 percent and the share of cobots is 13 percent. We see a significant change in favor of cobots, which have already doubled their share in the last four years.

What is the share of industrial robotics applications within and outside the automotive sector?

Currently, around 25 percent of all industrial robotics applications are within the automotive sector. Other industries that have a big share are plastic and metal, electronics and food. While automotive applications are almost stable, some of the other markets are growing with 20 percent and more increase in recent years.

What is Comau's goal in partnering with robotics software and AI provider Intrinsic?

Our partnership with Intrinsic aims to democratize access to robots. We use Intrinsic's "Flowstate" software platform for low-code programming of robots using drag and drop, i.e. for grouping application modules into flowcharts. As a technology and innovation partner of Intrinsic, Comau creates applications based on Flowstate.

An example of Comau's commitment outside the automotive market is the company's recently announced cooperation with the shipbuilding group Fincantieri in Trieste. What is this specifically about?

In cooperation with Fincantieri, we have developed the mobile welding robot "MR4Weld", which can travel along ships in a shipyard and perform welding tasks. We have signed a renewed letter of intent for further joint developments.

Your company's product range also includes exoskeletons. For which applications are they developed?

So far, our exoskeletons are not intended for medical applications. Despite this, they are developed for the well-being of workers, so that they tire less and their strain is reduced. One example is our battery-free, wearable robotic exoskeleton "MATE-XB", developed together with IUVO, a spin-off company of the Scuola Superiore Sant'Anna in Pisa, and in collaboration with Esselunga, a retail chain that acted as early adopter and validation and testing partner. In general, wearable robotics is a future technology, which we also underline through our partnership with Esselunga.

We also have a partnership with Seabery Augmented Technology: together we offer a training solution for robotic welding, suitable for educational centres and industrial companies. It is based on Comau's "e.DO" training robot and Seabery's "Soldamatic" training solution based on augmented reality.

Do you also see a market for your company's exoskeletons in medicine and rehabilitation?

Yes, the industrial market for exoskeletons is more developed at the moment, but there will certainly also be a market in medical and rehabilitation. It is no coincidence that we also work together with medical technology companies. We also see potential in crafts, construction and agriculture.

The interview was conducted by Andreas Knoll.