Applications From the Munich Show Floor

The Medical Technology Highlights of Automatica 2025

Quantum sensors for prosthesis control, robots that treat lung collapses in flight, the automated production of X-ray scanners or precise skull opening using a laser arm - the trade fair triple with the MedtecLIVE pavilion offered exciting MedTech systems for production, inspection and surgical use.

The trade fair triple of Automatica, Laser World of Photonics and World of Quantum set a new visitor record this year: around 47,500 visitors were welcomed to the technology shows at the Messe München 2025 exhibition center. Our discussions with suppliers and manufacturing partners in the medical technology sector show that The healthtech focus also benefited greatly from this. All our contacts were very satisfied with the number of people at the stand and the quality of the discussions on day 3.

Never before has medical technology been so present at Automatica and its sister trade fairs as this year. Robotics, lasers, automation and AI integration are core topics in medical technology. Both the MedtecLIVE Healthtech Pavilion, the MedtecSummit and the healthcare badge as a visible sign at the trade fair stands put the medical technology sector in the spotlight.

We show below some promising and, above all, practical applications for healthtech and medical technology and capture sound bites directly from the exhibition floor in Munich.

Treat injured persons in flight: TUM robots for emergency medicine

The TUM stand with its wide range of medical robotics applications was very popular: Among other things, the Technical University of Munich (TUM) presented a novel robotic system in Future Robotics Hall B4 at Stand 319, which for the first time enables the telemedical treatment of a life-threatening tension pneumothorax during an evacuation flight. The system was developed as part of the iMEDCAP project funded by the European Defense Fund and addresses both civilian and military deployment scenarios.

At the heart of the innovation is a robotic end effector that combines a decompression needle and catheter system with an ultrasound device. This enables the robotic arm to independently identify the relevant anatomical points for the needle insertion - Monaldi and Bülau points - using ultrasound and treat them in a targeted manner. The needle is inserted through the skin into the chest, the catheter remains in place and allows the trapped air to escape immediately. This saves valuable time to stabilize patients after accidents or gunshot wounds during transport.

The system is designed for use in areas that are difficult to access and can be remotely controlled by doctors via telemedicine. In combination with autonomous evacuation drones such as the Avilus "Grille" aircraft, initial medical care can be provided during the flight - a decisive advance for rescue operations in crisis and danger zones.

The modular platform is being continuously expanded: further robotic modules for the automated administration of medication via an intraosseous access, for haemostasis using a tourniquet or for injecting antidotes in CBRN use are under development. The aim is to develop robust, fail-safe technology that works reliably even under extreme conditions and thus significantly increases the chances of survival for seriously injured people - even where human helpers reach their limits. (uh)

Quantum sensors for medicine: thought control without a brain implant

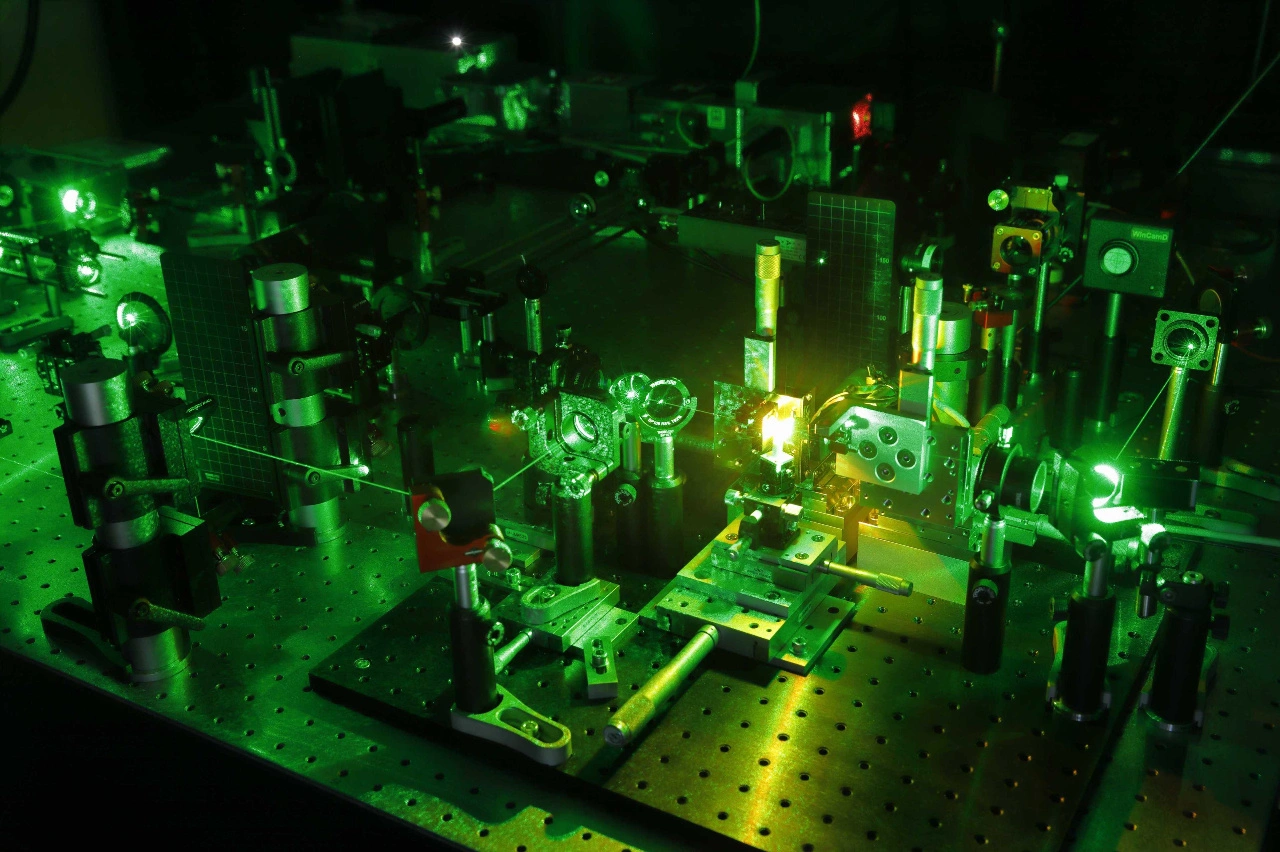

The optimization of complex electronic circuits, the visualization of individual bits in electronic storage media or a look into the tiny magnetic fields of the heart and brain to improve medical diagnostics - the Fraunhofer Institute IAF from Freiburg presented its projects relating to quantum technology in Hall 1 at the World of Quantum. The potential for medical technology is huge, as Lukas Kübler explains using the example of the NeuroQ project with Charité Berlin.

The resolution of current sensor technology is not yet sufficient to read brain waves directly from the surface of the head. Using highly sensitive diamond-based quantum sensors, the research team is working on enabling paralyzed people to precisely control neural exoskeletons without invasive procedures or implants. In the future, laser threshold magnetometers for neural interfaces will enable complex hand movements with such a non-invasive system. In contrast to many other quantum applications, the sensors based on home-grown diamonds do not need to be cooled and measure robustly and precisely even at room temperature.

According to Kübler, quantum technology is not yet ready for the mass market, but he is optimistic for the near future: »We believe that market entry for special applications in the next two to three years is realistic, especially in medical technology.« (uh)

Schaeffler: Semi-automatic X-ray tube production for Siemens Healthineers

At stand A5.310, Schaeffler Special Machinery presented an innovative semi-automatic assembly line for X-ray emitters, which was developed jointly for and with Siemens Healthineers. The "heart of the CT" consists of several hundred individual components, which can now be assembled by machine up to the EOL test. The intelligent production automation is intended to set new standards in medical technology production, especially as the production system can also be designed to be cleanroom-compatible.

The Schaeffler plant for the High Energy Photonics Center in Forchheim, the first fully digitized factory in which all core components for X-ray-based imaging are manufactured and assembled, relies on state-of-the-art integration: heat treatment furnaces, high-precision weighing stations (up to 80 kg with ±2 g accuracy), helium leak testers and comprehensive acoustic tests are directly integrated into the manufacturing process. A user-friendly human-machine interface ensures consistent worker guidance and increases ergonomics at the workplace. The system flexibly supports different product variants and processes test results and engineering data in real time using plant simulation.

Siemens Healthineers' High Energy Photonics Center focused in particular on the combination of flexibility, efficiency and precision. The integration of driverless transport systems optimizes intralogistics and enables seamless automation across all store floor stations. Schaeffler is thus setting new standards in the industrialization of medical devices and creating one of the most modern production facilities in Europe.

Also super exciting: At the same time, Schaeffler presented modular and scalable production solutions for the series production of humanoid robots in Munich. The systems cover all core components - from winding technology for electric motors to the assembly of actuators and battery technology. This allows manufacturers to react flexibly to increasing quantities and new requirements and means they are ideally equipped for the future of robot-assisted production. (uh)

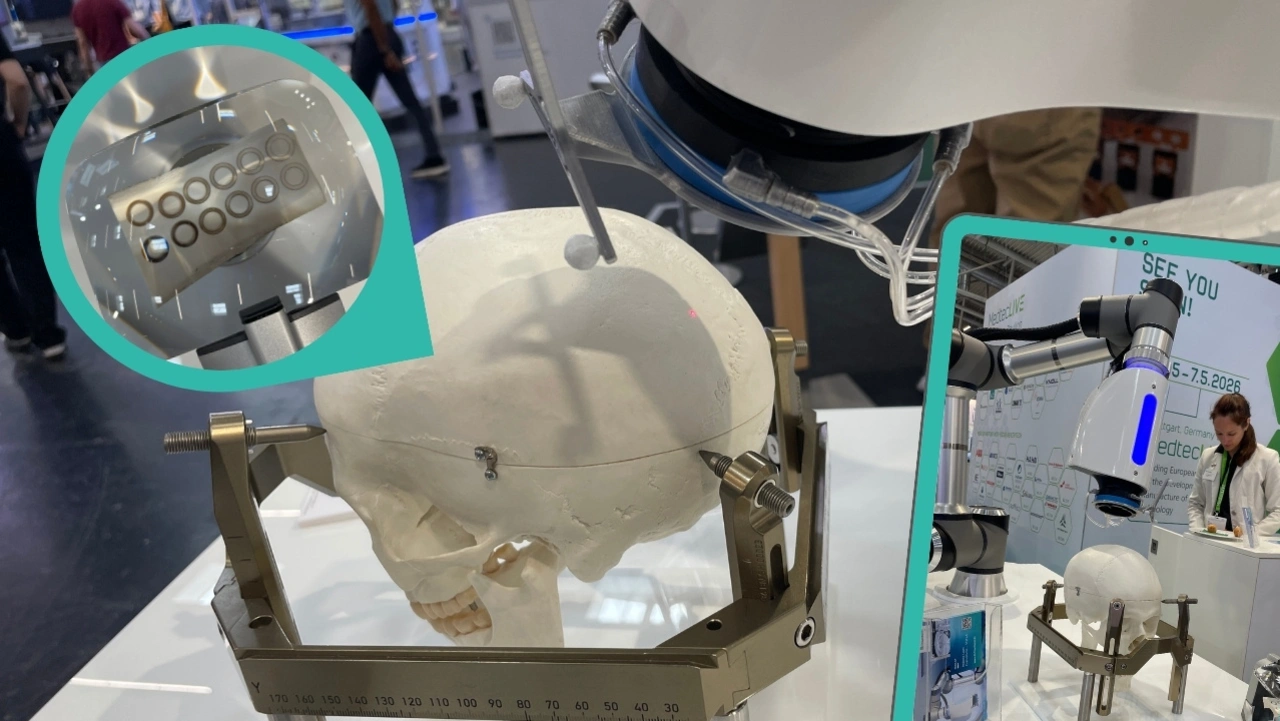

Skull opening by laser: Fraunhofer ILT presents new robotic arm for brain surgery

The Fraunhofer ILT presented the robot-based laser system "Stella" for minimally invasive brain surgery at the MedtecLIVE Healthtech Pavilion at Automatica: The combination of laser, sophisticated sensor technology and robotics is intended to set new standards, particularly for skull openings while the patient is awake: Surgery while the patient is conscious is necessary to test complex brain functions such as speech and motor skills, but noise and vibrations are very stressful for those undergoing surgery. The laser arm developed by ILT could therefore establish itself as a new surgical method with maximum precision on the doctor's side and minimal trauma on the patient's side.

"Our system enables extremely fine incisions and reliably protects the surrounding tissue," emphasizes Dr. Milena Zuric. "The heart of the laser application is a CO2 laser with 120 nanoseconds (ns), which emits short laser pulses in the mid-infrared spectral range around 9,3 µm, as well as an integrated OCT measurement system that continuously records the residual thickness of the skull during the procedure." This allows the robot to determine exactly how deep it still needs to cut and stops automatically just before the breakthrough - a decisive safety advantage. "This significantly reduces the risk for the patient and gives the surgeon unprecedented control," Zuric continues.

The short pulses ensure that no carbonization effects due to heat occur at the cutting edges. Thermal damage to the bone tissue would impede healing. Due to the short exposure time, the ns pulses remove the hard tissue without significantly heating the surrounding tissue. In addition, the inline OCT sensor system shows the surgeons how the removal of the bone tissue is progressing. Once the almost silent cutting process is complete, they can lift off the detached skull cap. After the operation on the brain, the bone flap is reinserted and quickly grows back together with the surrounding tissue thanks to the gentle laser cutting process.

The ILT technology, which is already being tested in some clinics but not yet on living people, is impressive in its details: thanks to high-precision actuators, cuts in the sub-millimeter range are possible. The robotic platform also has a modular design and can be flexibly adapted to different types of surgery - from neurosurgery to spinal surgery. Another highlight is the seamless documentation of all process steps, which further increases traceability and patient safety. (uh)

Whitebox development from ITK: robotics software for medical technology

Also at the MedtecLIVE Healthtech Pavilion, development service provider and software specialist ITK Engineering presented a robot that was developed as a telemanipulator for training surgeons at universities. The medical demonstrator combines software, the latest robotics technologies and AI and is already being used by medical students to practise surgical techniques in virtual reality - with full functionality over six degrees of freedom and including force feedback. The demands on the algorithms are correspondingly high - in the case shown, AI-based image processing translates the live images of the operating theater into line images that are transmitted to the robot in real time, thus enabling a realistic simulation.

As a subsidiary of Bosch (since 2017), ITK Engineering offers customer-specific solutions in the whitebox model. For example, if a medical device manufacturer wants to have software written for a robot-assisted application method, the OEM receives the complete source code and intellectual property rights.

ITK also showcased its in-depth medtech expertise with the robot demonstrator; over 200 of ITK's 1,200 engineers work in the medical sector alone. One special feature: the Bosch Connection enables the integration of industrial Bosch sensors into medical products, as Dr. Ulrich Sutter from the Medical Robotics division at ITK emphasizes: "We take a sensor from the Bosch shelf and develop customer-specific software for it - that's unique." At Automatica 2025, ITK Engineering positioned itself as a bridge builder between industrial robotics and medical technology - with a focus on practical training and flexible hardware-software integration. (uh)

MedtecLIVE Healthtech Pavilion as a hotspot for automation in medical technology

The MedtecLIVE pavilion in Hall 4 was an important pillar of the healthtech offering at Automatica and, alongside Bayern Innovativ's MedTec Summit and the VDMA's guided medical tours, one of the most important points of contact for medical technology developers in Munich. As the face of MedtecLIVE, Deputy Exhibition Director Silke Ludwig was very satisfied with the presentation: "Our exhibitors and we have had very good discussions so far. I am delighted that we have been able to communicate the topic of automation in medical technology so well here with MedtecLIVE customers. Great solutions, great expertise - and lots of visitors."

Ludwig sees great potential for the further growth of automation in medical technology, both on the production side and via AI in the digitalization of the patient journey. "Automation means digitalization. Due to the shortage of skilled workers, the need to reduce the workload of employees and the urgent need for cost efficiency in the healthcare sector, digital-based automation is an extremely important topic and will constantly develop and drive the industry forward."

In 2026, the next dedicated MedtecLIVE trade fair will take place in Stuttgart from May 5 to 7, and another joint MedtecLIVE stand is planned for 2027 as part of Automatica in Munich. (uh)

VMT: Visionary inspection for medical technology and pharmaceuticals

The HealthTech badge at the VMT stand 303 in hall A4 gave it away: Automation applications for medical (technology) can be seen here. In VMT's case, image processing systems specifically geared towards medtech and pharmaceutical production, which address critical quality assurance processes with AI-supported precision. Such as the fiber bundle inspection for dialysis filters, which uses a very high camera resolution to detect micro-defects caused by blunt cutting tools or faulty cuts, thus ensuring that all channels are clear for a trouble-free blood flow. The vision inspection ensures the functionality of each individual fiber in the filter bundles for blood washing.

Whether a single vision system or a fully integrated robot arm, VMT will be demonstrating at Automatica that the vision specialist offers any level of integration for specific customer requirements and supports all common robotic systems. A dedicated "Life Siences" development team provides medtech customers with tailored advice and support. For AI recognition, the Pepperl & Fuchs subsidiary has software pre-trained for inspection tasks, which is then »fully trained« for the specific application.

From simple counting tasks for balancing, where the correct number and position of vials or medtech packs in trays is checked, to the critical inspection of blood bags, where the medical vision system detects seam and seal defects, deformations or inclusions; fully automated test benches for automated inspection integration in the production line prevent high reject rates or even health risks: »For products such as dental implants, we prevent contamination due to inclusions in packaging,« emphasizes medical expert Maik Böckling at the VMT stand.

And when it comes to correctly legible packaging, intelligent code reading can serve as an early warning system and indicator for predictive maintenance: A multi-code reading system decodes even faded data matrix codes and recognizes grey scale changes that indicate empty printer cartridges - before misprints occur,« as Böckling explains.

A unique selling point for VMT is the AI-based and patented hygiene monitoring: Petri dishes with samples are placed manually or automatically by robot in test stands in which a vision system uses spectral analysis to automatically monitor and analyze bacterial and fungal growth. Despite the current challenging market situation, Böckling is optimistic: «We are seeing enormous growth in hygiene monitoring in particular - we are unrivaled here.« (uh)

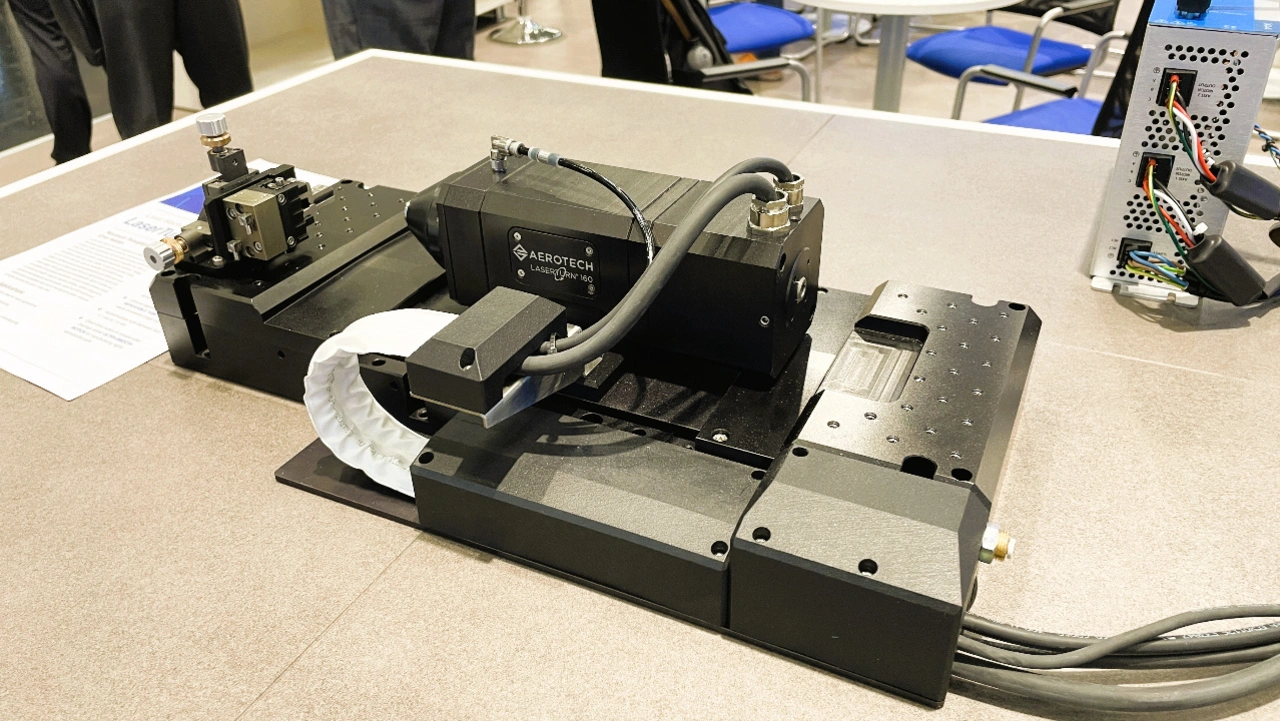

Aerotech presents LaserTurn160: Precision and throughput for stents and catheters

At Laser 2025 in Munich, Aerotech presented the LaserTurn160, a new generation of its cylindrical laser processing platform - a system specially designed for the high-precision production of medical components such as stents, hypotubes, catheters and guidewires. The Medtech laser system impresses with a combination of ultra-precise linear and rotary axes as well as intelligent material handling, which also precisely tracks long tubes.

Uwe Fischer, responsible for marketing at the Fürth branch, and Brett Heintz, senior application engineer at the headquarters in Pittsburgh, referred to the optimized dynamics at the American automation expert's stand: "With its new high-dynamic rotary axis, the LaserTurn160 increases process throughput by up to 40 percent compared to previous models," said Heintz. The rotation axis achieves speeds of up to 3000 rpm and accelerations of up to 8000 rad/s². Thanks to the direct drive and cross roller bearings, the movements are extremely smooth - resulting in tracking errors of just 1 micrometer, even with complex contours.

Flexible handling and high reproducibility: The table system processes hoses and tubes with diameters from 0.1 to 7.9 mm. A pneumatically operated dead-length gripper minimizes movements during gripping and reclamping, while an optional alignment gripper enables precise tracking of long hypotubes. "Medical technology manufacturers can use the LaserTurn160 to reliably and repeatably produce even the most delicate neuro stents or catheter structures," says Brett Heinz. The precise welding of hermetically sealed housings, for example for pacemakers, is also an important application.

Robustness for continuous industrial use: The LaserTurn160 is designed for use in harsh environments - dust, dirt and cooling water do not affect its service life of up to 25 years. The controller processes G-code profiles directly and enables fully automatic operation, which facilitates integration into modern production lines. "Our systems enable precision in the micrometre range with maximum throughput - that is our USP," summarizes Uwe Fischer. The team was very satisfied with this year's automatica in terms of the number of visitors to the stand and the good lead generated. (uh)