AMFitzgerald and MEMS Infinity

Piezoelectric MEMS for the Mass Market

AMFitzgerald has entered into a strategic and technical alliance with MEMS Infinity for the production of piezoelectric MEMS, a move that’s expected to significantly accelerate the commercialization of these types of sensors and actuators.

Over the past 15 years, thin film piezoelectric layers have been effectively and cost-efficiently deposited on silicon wafers. This manufacturing technology enables the production of entirely new MEMS-based products. One example is piezoelectric micromachined ultrasonic transducers (PMUTs), which are used in a variety of sensor types for industrial, automotive, consumer (especially smartphones) and medical applications.

PMUTs form the basis of fingerprint sensors in smartphones, for example, which can be used to identify the rightful user. PMUTs are the starting point for sensors that will enable the development of entirely new ultrasound devices no larger than an electric razor that will allow doctors to take ultrasound images of a patient's entire body and various organs. Devices based on this technology not only have the added advantage of being portable but are also significantly less expensive than conventional ultrasound devices.

Piezoelectric MEMS devices are highly versatile. While aluminum nitride (AIN) was the first piezoelectric thin film to be commercialized in high volume – and it’s ideally suited for MEMS-CMOS monolithic integration — PZT MEMS thin film is gaining ground.

PZT MEMS thin films span both sensing and actuator functions, and they’re a better fit for wafer-level or chip-level system electronics integration. Emerging applications of PZT MEMS include actuators that adjust the lenses in cell phone cameras and lidar systems that focus on the desired objects (optical image optimization). MEMS microphones and micro-speakers, MEMS gas sensors, and microfluidic components are other complex applications for which PZT MEMS is a better fit than AIN thin films.

"In general, piezoelectric MEMS today not only achieve better performance than capacitive MEMS, but they are also easier and less expensive to manufacture," said Dr. Alissa Fitzgerald, CEO of AMFitzgerald, who founded the company in 2003 as a specialist in the design and development of MEMS-based systems for industries such as aerospace, industrial and medical. Since then, AMFitzgerald has helped hundreds of customers, from start-ups to Fortune 100 companies, develop MEMS technologies for use in commercial products. The company sees great promise in piezo-based MEMS (including PZT MEMS) because, first, the quality of piezoelectric materials has improved in recent years and, second, equipment manufacturers have developed machines that can deposit piezoelectric thin films cost-effectively and in large quantities.

As a result, AMFitzgerald has formed an alliance with MEMS Infinity to accelerate the introduction of PZT MEMS products. Sumitomo Precision Products’ new foundry service, MEMS Infinity, manufactures MEMS products based on 150mm and 200mm wafers. MEMS Infinity’s 20,000 square foot clean room is located in Amagasaki, near Osaka.

MEMS Infinity's specialty is its ability to deposit various piezoelectric materials as thin films on MEMS transducers to convert mechanical energy into electrical energy or vice versa. "This makes MEMS Infinity a leading manufacturer of piezoelectric MEMS; there are very few manufacturers in the world that have mastered this technology," says Alissa Fitzgerald. MEMS Infinity offers two main types of PZT material: Poly-PZT is primarily for use in actuators, while Epi-PZT is suitable for both sensors and actuators.

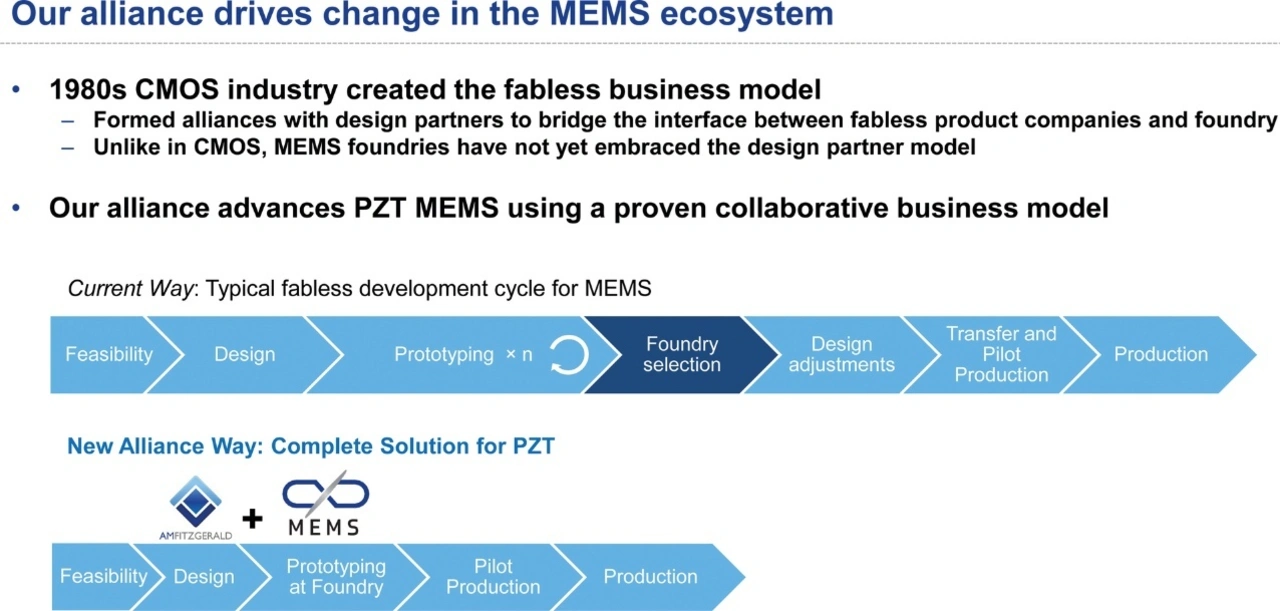

However, it has been very difficult for customers to obtain commercially available materials of the right quality during the development phase, when only small wafer quantities are achieved. This has been a major problem. If they can only use research-grade materials in the prototype phase, which do not reach commercial quantity levels, this significantly delays product development. This was because the prototypes had to be made first, and then the foundry had to be selected. There was no seamless transition from prototyping in the lab to volume production in the fab. "Through our alliance with MEMS Infinity, we will significantly change this: We now offer customers a unified environment from the start of development through prototyping to volume production, with access to the highest quality PZT materials from day one."

This will significantly accelerate the development process from design to volume production, lowering the barriers to entry into the technology and reducing costs. "What has been common in the foundry model for CMOS IC production, where foundries seek out EDA companies as design partners, is almost nonexistent in the MEMS world," said Alissa Fitzgerald. The collaboration with MEMS Infinity will change that: "Of course, it always depends on the type of MEMS, but I expect the existing fabless development cycle from design to prototyping and pilot to production to be accelerated by 50 percent. The partnership between AMFitzgerald and MEMS Infinity eliminates the need for prototyping in the foundry, foundry selection, design adjustments and transfer to production, all of which are time-consuming project phases.”

According to Dr. Fitzgerald, this will open up entirely new market sectors and growth opportunities for piezoelectric MEMS: "I see the medical sector in particular, especially PMUTs for use in ultrasound devices, as very promising. But PMUTs will also be used in large numbers in autonomous systems for transportation tasks such as drones, in driver assistance systems in cars, and in the new devices for the metaverse.”

But are PZT thin films really the material of the future? There are alternatives that do not contain lead, such as AlN, scandium-doped AlN (scAl N), and potassium, sodium, and niobium (KNN) materials. AlN was the first piezoelectric thin film to find its way into commercial products. Today, the material is used in RF filters, oscillators, microphones, fingerprint sensors, and touch sensors, among other applications. "AlN is certainly suitable for monolithic MEMS-CMOS integration, but it does not have the functionalities of PZT. It can hardly be used in actuators," says Fitzgerald. Although she considers KNN an interesting material, it is still in the development stage.

She rules out the possibility that PZT will be phased out because it is not RoHS-compliant, as it contains lead, because it is simply not substitutable and there will be exemptions for a long time to come. "PZT is the material of choice for many types of MEMS because it has the best properties and, in many cases, cannot be easily replaced by alternatives. It can be found in many fast-growing MEMS types and will continue to conquer new application areas.”

MEMS Infinity

In early 2024, Sumitomo Precision Products (SSP) expanded the MEMS ecosystem with foundry services from MEMS Infinity. MEMS Infinity manufactures MEMS on wafers with diameters of 150 and 200 mm. SPP has decades of experience in the MEMS industry. In the mid-1990s, SPP acquired UK-based STS, which built equipment for manufacturing MEMS using the Silicon Deep Reactive Ion-Etch (DRIE) process developed by Bosch.

"With our new foundry service, we aim to accelerate the commercialization of high-quality MEMS," said Masahiko Tanaka, Managing Executive Officer of SPP. According to Yole Intelligence, the MEMS market will grow at a compound annual growth rate of 9 percent between 2021 and 2027 to more than $22 billion. MEMS for high-growth markets such as automotive, aerospace, industrial and medical, for which MEMS Infinity manufactures, will account for 50 percent of this growth. One of MEMS Infinity's specialties is the production of thin-film PZT MEMS, a material that only a few foundries in the world have mastered, including Rohm, TSMC, STMicroelectronics, Bosch and Silex Microsystems.

There is currently no such foundry in the U.S. For the production of PZT MEMS, MEMS Infinity has allied with AMFitzgerald to produce these MEMS devices in an integrated process flow for the first time, which will significantly reduce time-to-market. In addition, it will make these products available to a much broader set of interested parties, reducing their development risk and lowering development costs.