Electronic Switches For Relais

Digital-Micro-Switch Technology Now Available

Fortsetzung des Artikels von Teil 1

Shrinking product size and reducing manufacturing steps

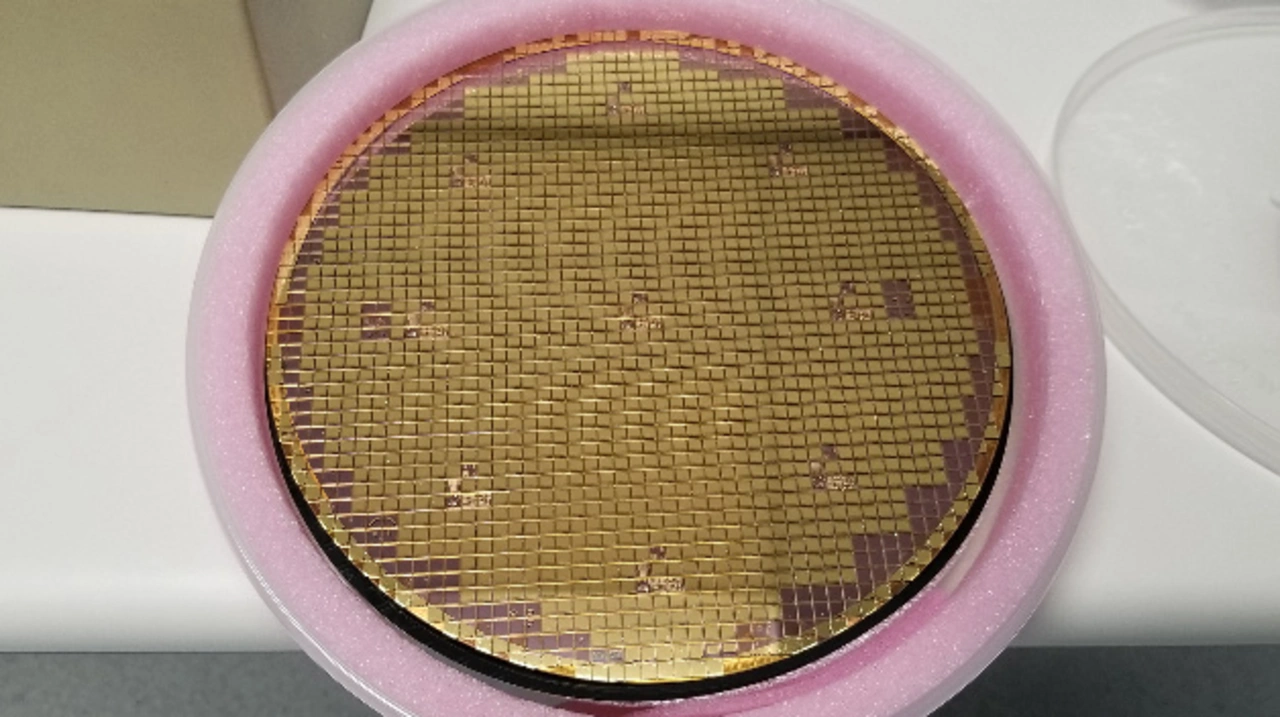

Innovations in advanced alloys, processing, and packaging have allowed Menlo to shrink the size of its products by more than 60 percent when compared to previous generations. Menlo’s material science breakthroughs have also enabled a simplified manufacturing flow, representing a 30-40 percent reduction in manufacturing steps when compared to typical CMOS processes. This simplification helps to reduce manufacturing costs. Together, these advancements play a key role in Menlo’s vision of reducing the size, weight, and power consumption of critical electronic systems.

Menlo’s unique approach allows it to offer a new kind of power handling in a micromechanical device with superior electrical performance, size, cost, and reliability as compared to both traditional mechanical relays and solid-state devices. Menlo’s switches are built in a structure smaller than a human hair, yet they have been proven to be capable of handling kilowatts of power – while operating 1000x faster and lasting 1000x longer than typical mechanical relays.

- Digital-Micro-Switch Technology Now Available

- Shrinking product size and reducing manufacturing steps

- Corning’s Through Glass Via Packaging Technology