In-vehicle Networking Technology

Are we ready for the future?

Fortsetzung des Artikels von Teil 1

The car as a software product

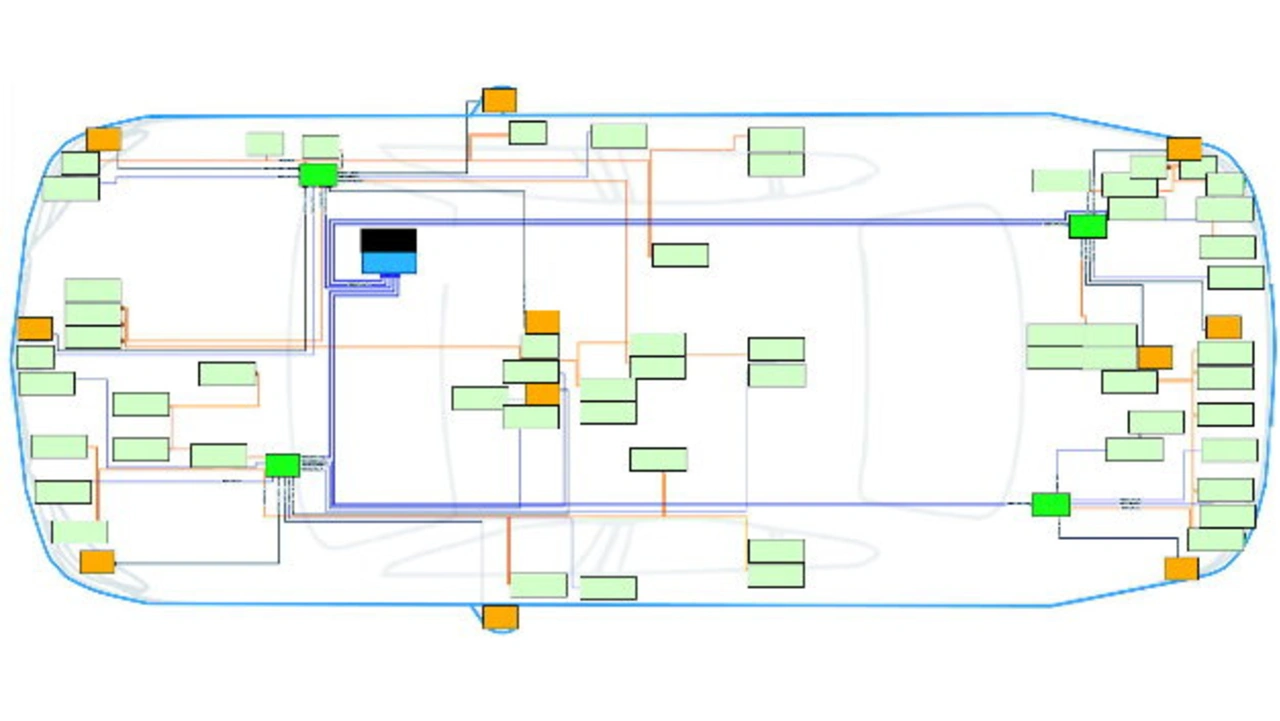

It is immediately evident that such a system would result in huge changes in the wiring harness and harness production. Today’s tailor-made wiring harnesses could be replaced by smaller, less complex, machine assembled harness segments. This being within the hard currency of car manufacturers, this message is easily conveyable. Consequently, such an (often-called “zonal”) architecture is being discussed frequently.

But, looks are deceiving. Figure 2 is not only about changing the harness production, it is about empowering the software defined vehicle. In the truly digitized world the hardware follows the requirements of the software and leaves room for extensions. As the main difference is not hardware, this is a lot more difficult to visualize and thus also harder to convey!

The car as a software product

Handling the car as a software product (with a mechanical functionality as a desired outcome) is the real revolution. The goal of this revolution is to enhance customer experiences by being able to offer innovations faster and to be able to offer different types of innovations, leaving the restrictions of today’s rigid development circles behind. Of the various transformations such a change requires within the car manufactures, this article addresses the communication infrastructure inside vehicles.

A core feature within a distributed software system is the accessibility of computing power and data as well as a separation between hardware and software. Further important aspects are machine learning, update- and upgradeability, software re-use, third party integration, etc. The ideal (in-vehicle) network for such a system is robust, flexible (in data rate as well as topology), and supports fundamental communication principles in respect to services, security and various Quality-of-Service (QoS) elements. A communication technology that supports these requirements exists: Ethernet.

Ethernet-based communication follows a strict protocol layer separation. It is therefore very flexible and adaptable and provides the foundation for the exchange of data in a large number of industries. It inherently supports service-based communication and state of the art security is available. Since 100BASE-TX Ethernet was first introduced in the car industry for flash and diagnosis in 2008, its capabilities have been significantly extended in respect to data rates and QoS. 100BASE-T1 (100Mbps over a single Unshielded Twisted Pair (UTP) cable) had Start-of-Production (SOP) in 2013. The first SOP of 1000BASE-T1 (1Gbps over a single UTP cable) is expected any time now. QoS protocols from the Audio Video Bridging (AVB) standards have been used in cars since 2015.

Owing to the switches used in an Ethernet-based network, topological flexibility and extending the network is possible without necessarily mitigating the available bandwidth. This is very different to legacy automotive In-Vehicle Networking (IVN)-technologies like CAN or FlexRay. For those two, the available data rate is simply shared among all participants. The network size is limited (also because of physical constraints) and extensions, e.g. to another CAN network, have to be realized via gateways. In order not to unnecessarily strain the available data rate in the attached CAN networks, gateway tables have to know exactly which message is needed on which attached network, so that only the required messages are being forwarded. This rebuilds the functionality that is inherent in the Ethernet switches anyway and does not have to be provided additionally in an Ethernet-based network.

- Are we ready for the future?

- The car as a software product

- First samples of 10Mbps-Ethernet

- How to realize a smooth transition?