Embedded Sensors

Wireless and autonomous embedded digital strain sensor

Metal foil strain gauge have been widely studied and used in the industry for the past 60 years. These resistive strain sensors are made of a metallic conductor on a flexible polyimide substrate.

The changes in the geometry of the metallic foil when stress is applied to the substrate, induce a variation of the electrical resistance. Typical metal foil strain gauges have a linear dependence of the electrical resistance with the strain applied. Their gauge factor, which is the ratio of relative change in electrical resistance to the mechanical strain, is close to 2.

One of their major drawbacks relies in their low strain sensitivity which drastically limits the measurement of very small strain. Another one is their low resistance at rest typically below 1 kΩ, which requires special precautions to measure the resistance variation and instrument these sensors. These strain sensors are also complicated to use. Their installation requires a precise bonding of the strain gauge onto the test object, performed by a trained operator. One must also weld the electrical wires and apply a protective coating.

The aim of this article is to present a new digital strain sensor designed to overcome these issues and provide new strain sensing solutions for never addressed applications. The work presented in this article is the result of a collaboration between two companies: Nanolike and Stimio.

Nanolike finds its origin in the exploitation of nanotechnologies. Its expertise in this field enables them to benefit from the advantages of the physical properties of nanoparticles to develop a more efficient generation of sensors, mixing a miniaturized size and an ultra-low power consumption.

Stimio is a company specialized in Internet of Things (IoT) and Low Power Wide Area Networks (LPWAN). Stimio designs and manufactures connected objects for applications such as Industry, Logistics, Transportation and Agriculture.

Digital imbedded strain sensor

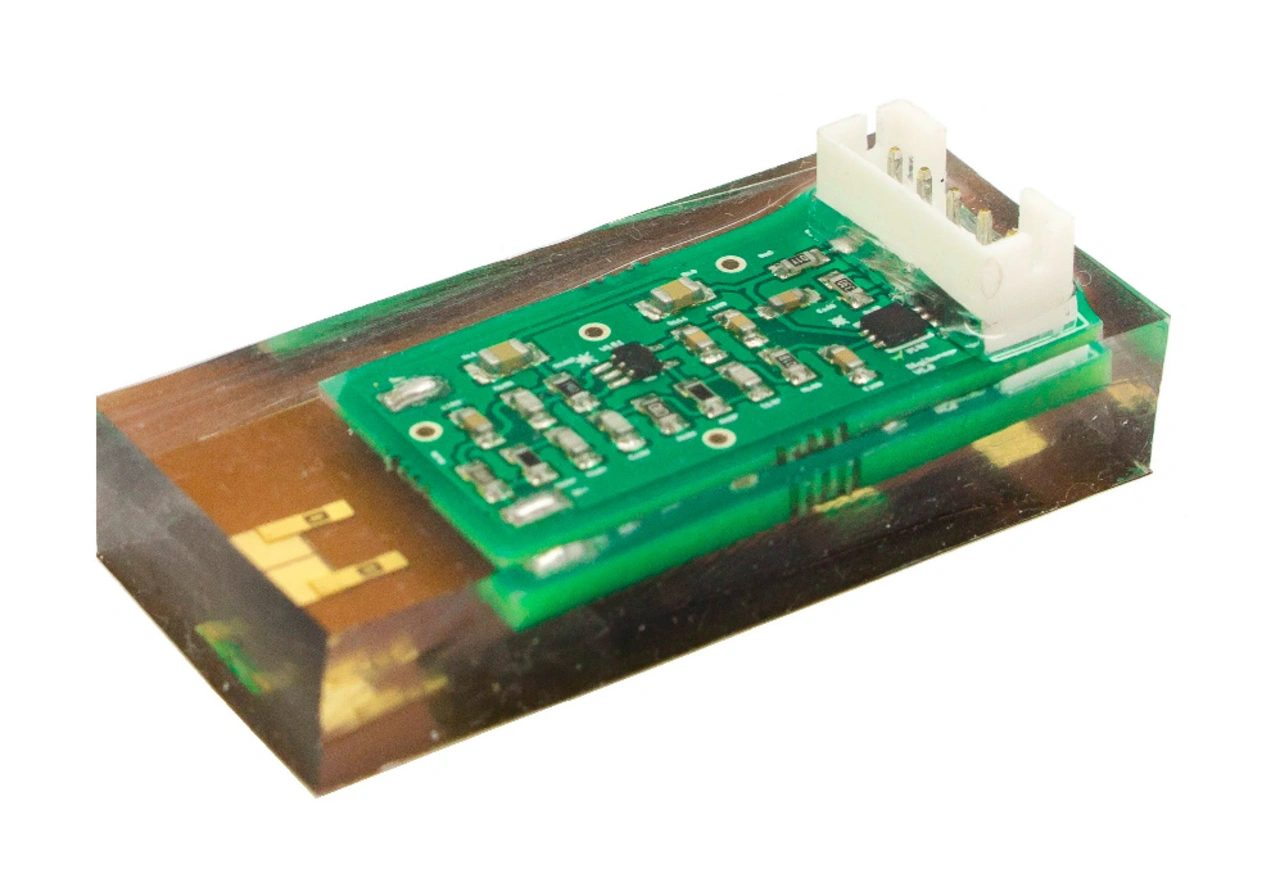

Nanolike strain sensing solutions use the unique properties of gold nanoparticles (NPs) coated with organic ligands. The nanofabrication process to build the active area of the strain gauge uses a bottom-up approach as opposed to top-down processes used in microelectronics. NP-based strain gauges are fabricated by assembling the gold NPs in the form of an array of wires, onto a flexible polyimide substrate. The NP wires are then connected by two gold electrodes to obtain a resistive sensor. This NP-based strain gauge is then integrated along with an electronic board into a polymer matrix as can be seen on the Fig. 1. One must consider that in the particular case of Fig. 1a the polymer is transparent for the need of the picture but it is not usually the case for commercial product (Fig. 1b). Part of the electronic for the signal processing is therefore directly integrated in the sensing element. The thickness of this embedded strain sensor is 7 mm, the length 40 mm and the width 27 mm.

Depending on the use case, the direction of the strain measurement can be chosen parallel to the long side or the short side. The polymer matrix provides a strong protection of the sensor against mechanical damage, chemicals and weather conditions. It also eliminates the need of a supplementary protective coating necessary for conventional metal foil strain gauges.

The current flow in the nanoparticle assembly is driven by the tunnel conduction between neighboring nanoparticles through the ligand barriers. When a strain is applied to the substrate, the distance between the nanoparticles increases, increasing the length of the tunnel barrier. Therefore, the electrical resistance of the strain gauges varies exponentially with the strain applied to the substrate.

The tunnel conduction through the organic ligand coated nanoparticles gives these gauges a very high sensitivity, with a gauge factor more than 10 times the one of conventional metal foil strain gauges for a maximum strain applied of up to 0.2 %. Besides their high gauge factor, these nano sensors present a very low electrical consumption because of their high resistance at rest, adjusted between 100 kΩ or 1 MΩ. That resistance at rest reduces the electrical consumption of the strain gauge by a factor 100 to 1000 compared with standard metal foil strain sensor. A high resistance at rest combined with a high strain sensitivity means low power consumption, and no need to pay attention to the resistance of the “cables” used to instrument the sensors. This is one major advantage especially when designing sensing solution for wireless and autonomous applications. Taken together, these properties support the strong potential of the digital strain gauges for never addressed before applications in the IoT.

- Wireless and autonomous embedded digital strain sensor

- Electronic, communication, power consumption

- Use case

- Conclusion