Interview on ModBlox7

Unite industrial PC and 19-inch system

Members of the PICMG are working for the first time on an open standard for industrial computers. So far, each IPC manufacturer has been doing its own thing. EKF Elektronik explains the advantages of a standard, how far the specification is advanced, and what ModBlox7 looks like exactly.

Markt&Technik: Mr. Kleeberg, how did the idea for ModBlox7 come about within the PCI Computer Manufacturers Group (PICMG)?

Bernd Kleeberg: The idea behind ModBlox7 is to create a modular standard for industrial PCs (IPCs) that is equally suitable for wallmount, DIN rails and 19-inch mounting - and combines both worlds. It is important for us to design the systems to be flexible and interchangeable, and to do so in a cost-effective manner - more cost-effective than is the case with previous backplane or 19-inch systems. And more flexible than with previous IPCs. The standard must be able to withstand the high cost pressure of the current era, cover the necessary bandwidths and be inexpensive to implement. Within the PICMG ModBlox7 group, many interested companies are participating in the specification and its implementation. The board is formed by the companies Ci4Rail, Eltec and EKF Elektronik.

Why not stick with the old 19-inch system?

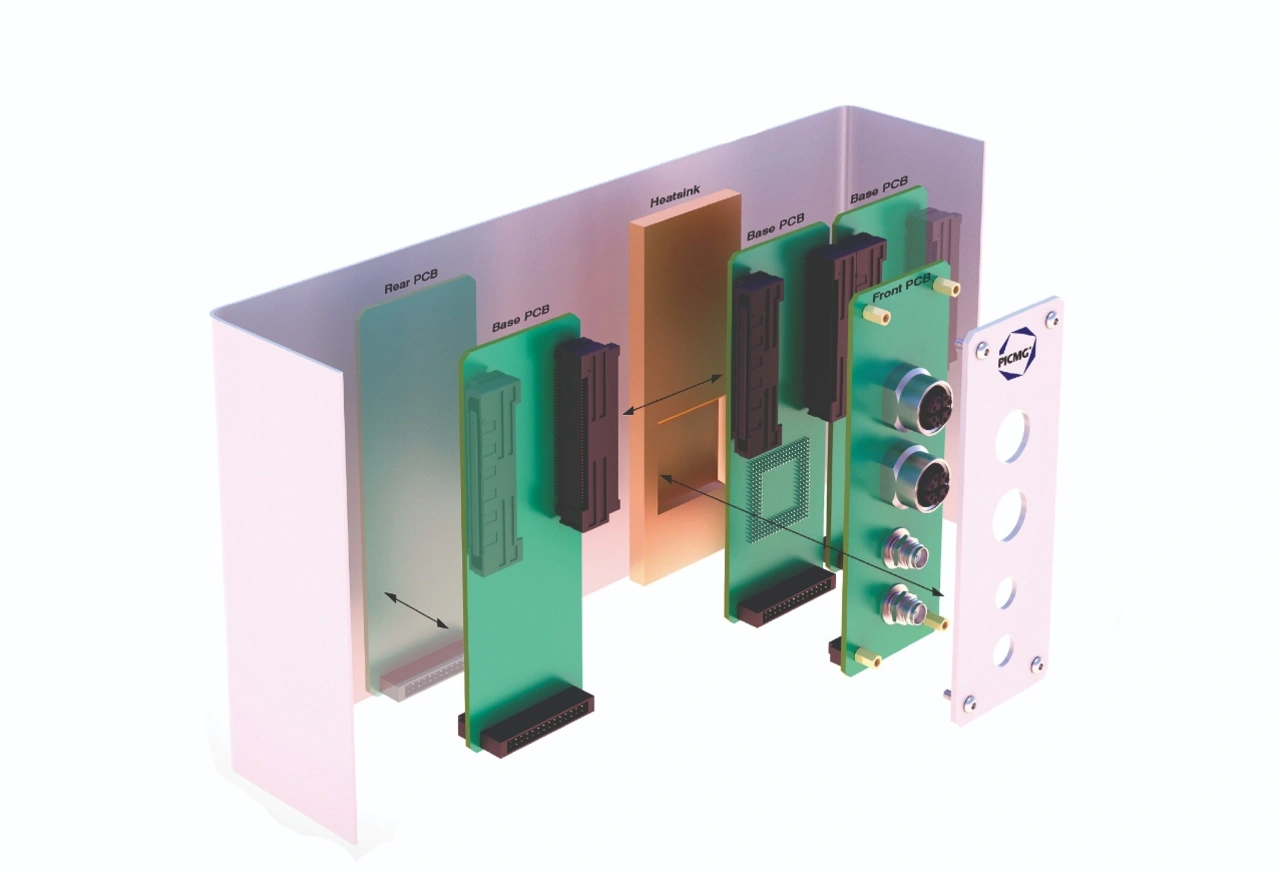

Kleeberg: In the 19-inch sector, the mechanics cause high costs. If we want to expand the market, we quickly reach the limits of profitability. So we need new ideas: modular, expandable, cost-effective. This is implemented with a direct board-to-board connection without a backplane. This is the only way to inspire customers and implement new projects.

How is a ModBlox7 IPC structured, and what installation situations is it designed for?

Kleeberg: We define certain standardized fixing points in the specification. This means that a user can flexibly choose which mechanical mounting he would like to have, but always with the same fixed points. This makes it easy to interchange modules. In principle, we have agreed on the 19-inch, DINRail and WallMount mounting types for the standard. For example, users can simply replace old 19-inch systems with ModBlox7.

Manuel Murer: All ModBlox7 modules have a mounting size of 7 HP or a multiple of this. According to the specification, a maximum of 12 modules, meaning 84 HP, can be combined to form a 19-inch system. If fewer modules are required, the C-profile can simply be shortened by the respective length. This means that there are no empty slots and no backplane is required. We decided on this system at PICMG because it is most cost-effective to implement.

So far, there is no standard for IPCs. Which advantages do you expect to gain from the standard?

Kleeberg: With a standard, a customer is no longer dependent on a single manufacturer and can choose components from a portfolio of several companies. On the one hand, this corresponds to the second-source idea; on the other hand, not every manufacturer offers every component. Together, this results in a comprehensive ecosystem of system manufacturers, who are responsible for the overall concept, and add-on manufacturers, who offer special I/O modules, for example. In sum, a developer has a broad selection of solutions for a project. We also increase the attractiveness for suppliers of special modules, because they also have more customers at their disposal. In addition, because it is an open standard, every embedded company can have individual modules developed or develop them themselves.

The specification is currently being worked on. What steps still need to be taken and by when should it be completely ratified?

Kleeberg: The draft of the specification is very far advanced - the working group within PICMG is permanently working on it and currently meets weekly. We want to adopt the standard by embedded world 2023 and present it to the public for the first time there as a kick-off. However, there are already the first prototypes and the first products on the market, as a de facto standard, so to speak.

Which product is EKF currently developing?

Murer: We have conducted a market analysis to see what customers expect from an open IPC ecosystem. Based on the analysis, we will - according to the current status - develop an AI-based platform. It will operate on one of our CPU boards with Nvidia's Arm-based Jetson module and serve as both a master and slave board. In addition, there are to be various I/O modules, especially for single-pair Ethernet.

Kleeberg: In addition to Nvidia, we are also relying on Intel processors. There will also be products for this in the near future. However, it is still a bit too early to talk about this. First we have to adopt the standard - perhaps we can even announce our first products at the same time.

Is there already an interest in ModBlox7?

Murer: We were able to observe initial interest at the InnoTrans trade show in Berlin. There is also a flyer from PICMG that contains initial information about ModBlox7. This has already generated a lot of interest from companies in various industries.

Which volumes do you want to produce?

Kleeberg: I can't predict that at the moment, but I expect very high quantities. IPCs based on the ModBlox7 standard can be used almost anywhere where »normal« IPCs are currently doing their job. The possibilities are huge – and much greater than with our current systems. For example, the components meet the requirements for the railroad or industrial sectors, for example for programmable logic controls.

Which interfaces are available and what about connectivity?

Murer: Our market research has shown that there are already ideas and products for all typical interfaces - either CAN, digital and analog I/O interfaces or WiFi. We are also pursuing the idea of developing PCI Express and M.2 carrier cards that can also serve as mass storage cards. In addition, all types of fieldbuses are set. Furthermore, we want to develop GNSS modules, some of which work with tenfold accuracy.

Which applications is ModBlox7 interesting for?

Murer: The member companies of our PICMG working group have different market orientations. Ci4Rail or Eltec, for example, are more active in the rail sector. We develop industrial applications for measuring and testing or automation. I see less use for ModBlox7 in the automotive sector, perhaps as a data logger with single-pair Ethernet function.

In addition, the standard provides redundancies. This means that all parts of the system, for example the power supply, can be set up redundantly - this is particularly interesting for customers who place high demands on system stability.

Markets&Markets forecasts an increasing demand for IPCs, almost six percent per year until 2026. How do you see this demand emerging?

Murer: The demand is mainly driven by digitalization and the IIoT. Devices and assemblies collect data in logistics, for example, and they have to be processed and evaluated. The same applies to transportation - even in trains, more and more data has to be processed and analyzed. The public sector is also creating jobs for digitalization, because municipalities and cities are becoming increasingly digital - keyword: smart cities. All of this increases the demand for computing power and thus for industrial computer systems - across all industries and sectors.

How about the current component availability? Are you getting the components you need to produce an IPC?

Kleeberg: On the one hand, we have greatly increased our storage capacities. On the other hand, the general situation is gradually improving. Components that recently had a delivery time of over 52 weeks are currently available within 16 to 20 weeks. Nevertheless, many components are still not available from stock at present. The future economic situation is also difficult to predict. We will have to wait and see how it evolves. However, I think the supply of components will improve gradually.

Mr. Kleeberg, Mr. Murer, thanks a lot for the interview.