Fraunhofer IZM

Segmented Micro-Batteries for Wearables

In order to power sensors in wearables, these batteries must adapt perfectly to the material and at the same time fulfill the requirements for electrical power. Researchers at Fraunhofer IZM have now created a segmented battery that resembles a link chain.

Wearables are used in medical applications, for example, to collect data without disturbing the patient's everyday life, such as in long-term ECGs. Because the sensors are integrated into the clothing, as well as being lightweight and flexible, the patient's heartbeat can be conveniently monitored. This technology is also used in everyday life, for example as a fitness tracker measuring the pulse rate during jogging. Wearables are predicted to grow rapidly, reaching a market value of 72 billion euros by 2020.

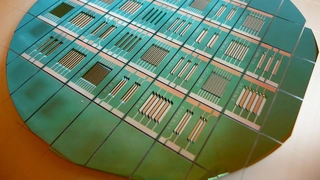

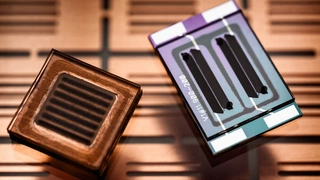

Powering smart textiles is a technological challenge. Technical requirements such as durability and energy density have to be coupled with specific material requirements such as weight, flexibility and size. One example is an "intelligent" wristband, developed by the Fraunhofer Institute for Reliability and Microintegration IZM to the prototype stage. It can literally collect firsthand data. The technological trick behind the silicon tape is to use three green shimmering batteries. With a capacity of 300 mAh, the batteries supply the wristband with power. They store 1.1 Wh of energy and have a self-discharge of less than three percent per year.

Thanks to these parameters, the new prototype has a significantly higher capacity than existing smart bands on the market and can therefore also power more advanced portable electronics. The available capacity is more than enough to power a conventional smart watch without loss of battery life. According to the researchers, the prototype also outperforms established products such as current smart watches, where a battery is placed in the watch case and not in the wristband.

Micro-Batteries for Wearables

Success by Segmentation

Dr. Robert Hahn, scientist in the RF & Smart Sensor Systems department at Fraunhofer IZM, explains the recipe for success: »The energy density of flexible batteries is poor – a segmented concept is better«.

Instead of making the batteries mechanically extremely flexible at the expense of energy density and reliability, the institute is working on designing very small and powerful batteries and developing optimal assembly techniques. The batteries can be bent between the segments. Thus the smart band is flexible on the one hand and provides much more energy than other smart bands on the market on the other hand. The principle is similar to that of a link chain, in which a chain is composed of many solid links.

In the development of wearable batteries, Fraunhofer IZM has combined new concepts with many years of experience with customer-specific development: »In cooperation with the companies, we develop the matching battery«, explains the graduate electrical engineer. In close collaboration with the customer, the power supply requirements will be defined. Parameters such as shape, size, voltage, capacity and electrical power are customized and a power supply concept will be developed. Additionally, customer-specific tests are carried out.

Smart Plaster to Measure Sweat

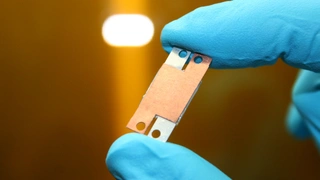

In 2018, a new project in the area of wearable technology was launched at the Institute: the smart patch. Together with the Swiss sensor manufacturer Xsensio, the EU-funded project aims to develop a patch that is able to measure and analyse the sweat of the user without delay. The sweat can be used to derive information about the state of health of the user. A comfortable and real-time analysis therefore offers the possibility to track and monitor recovery processes much better.

Fraunhofer IZM is developing the assembly concept and the power supply for the sensor that measures perspiration. The objective is to integrate batteries that are extremely flat, flexible and lightweight. Various new concepts are being developed for this purpose. For example, an encapsulation made of aluminum composite foil would be possible. The choice of materials also takes into account that they have to be inexpensive and easy to dispose after use. Ultimately, plasters are disposable products.