Modular platform for embedded vision

Save time and costs, minimize risks

To reduce development time and costs for embedded vision systems, hema electronic has developed a modular embedded vision platform. In this interview, Managing Director Oliver Helzle talks about the advantages of the platform approach and the possibilities offered by customization.

Mr. Helzle, in embedded vision, standard electronics quickly reaches its limits. How much flexibility for individualization does the hema embedded vision platform offer?

Oliver Helzle: It’s true – every electronic system used for an embedded vision application is different. Nevertheless, there are interfaces, functions and requirements that always reoccur – be it SDI or MIPI, real-time capability or IP cores for processing and merging sensor data, for overlays or coding for a variety of outputs. The many projects we have already completed have resulted in a design library with currently around 45 building blocks. For all standard interfaces, we have layout blocks and circuits that can be individually combined and supplemented with new or customer-specific elements. The same applies to the software, where we can draw on extensive developments and existing FPGA designs.

Where are the limits here? And is, for example, the board format freely definable?

Helzle: We can assemble many embedded vision electronic systems almost 100 % from our design library and only have to add a few customer-specific circuits or functions. Then within a few days customers receive a circuit diagram and, in the best case, a prototype within six weeks. This is delivered already based on industrial-grade circuits and is equipped with components that can later be used in series production. We can take the board format, connector arrangements, etc. fully into account. If the requirements are very complex, it may take a few days longer to produce a prototype but in any case, customers receive a product that is very close to their series hardware.

How scalable is the computing power of the electronics?

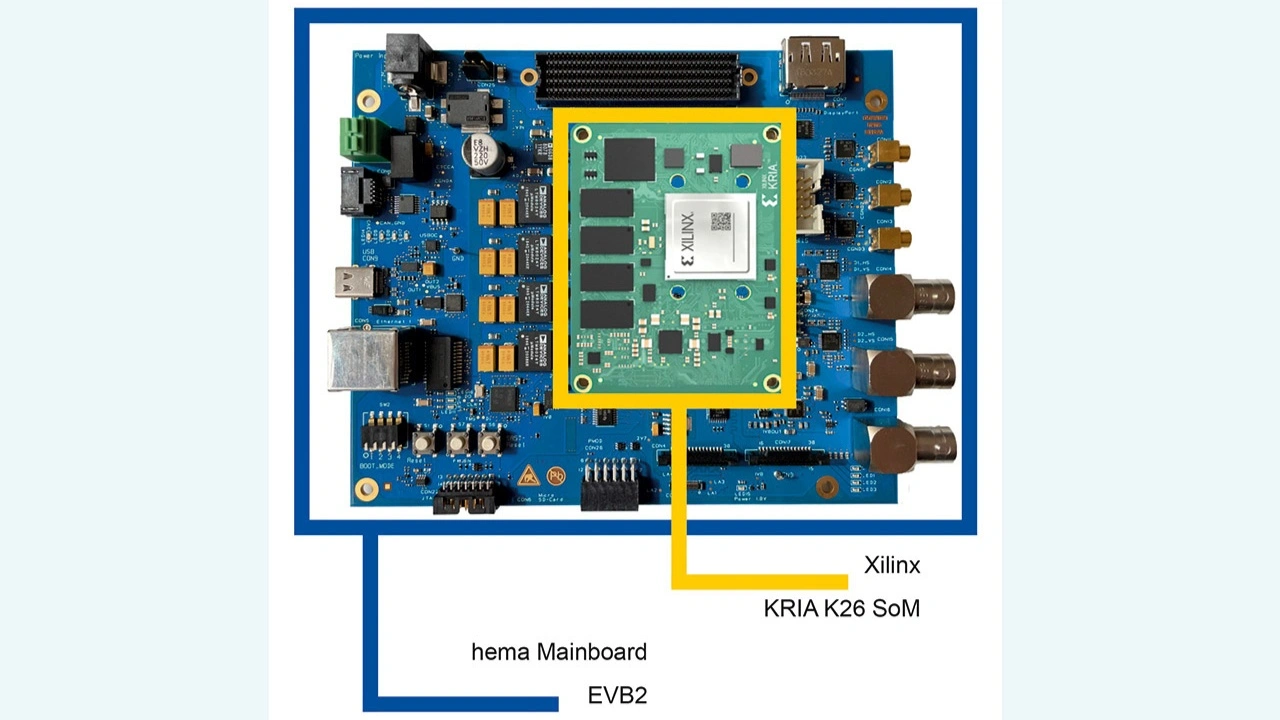

Helzle: With the hema embedded vision platform, we combine individual mainboards with system-on-modules (SoMs), for example from Xilinx. These are available with different performance – in other words, with different numbers of FPGAs and Arm processors. Furthermore, we have also developed mainboards that use multiple SoMs. Programming for the interaction of processors and for the optimal utilization of all SoM features including ISPs, GPUs, etc. are specialities of hema. Designs with mainboards and SoMs also enable developers to bring different product variants or upgrades to market quickly and easily. This also reduces the complexity of the mainboard and saves time and costs during development.

Software accounts for a large share of development today. How do you support your customers in this?

Helzle: For us modular electronics development is not limited to hardware alone: We deliver our electronic solutions including a customized board support package and undertake the customer-specific programming of the FPGAs. In addition, to stay with the Xilinx example, we are a Xilinx Alliance Program Member and can thus offer our customers access to the complete environment of tools and software, for example for the new »Kria« SoMs. We also work with third-party vendors who port their software to our hema embedded vision platform. Some applications examples of AI and machine learning can be seen at our booth. But last not least, customers receive their hardware very quickly and can thus move directly into the development phase of their own projects. This momentum can be maintained and re-applied right up to series production thanks to the near-series prototypes.

What plans do you have for the hema embedded vision platform in the future?

Helzle: During the pandemic years we were able to win numerous projects because companies simply used us as an extended workbench and were thus able to continue developing their projects despite limitations in their own internal operations, alternatively we were able to work on their systems in parallel. This has encouraged us to continue on this path. In the future, we will integrate more SoMs into the platform and expand our upstream services in the area of hardware and software so that we can support even more companies to implement their projects quickly, efficiently and with low design risk.

Thank you for your time, Mr Helzle.

Faster to series production with hema, Xilinx Kria and partners

Hardware and software integrated: At embedded world, hema electronic and its partners will demonstrate for the first time how companies can accelerate their developments with the hema embedded vision platform and the Xilinx Kria Environment. Within just a few weeks, customers receive an almost production-ready prototype of their end-device and benefit from comprehensive developer tools and customized software from hema partner companies. The modular electronics design kit was developed by hema for embedded vision applications and electronics for multi-sensor systems. Xilinx Kria SoMs, which were specifically designed for use in applications such as smart cameras, embedded vision, machine vision and smart city, are an ideal complement to this. The Xilinx »Kria K26« was the first SoM to be integrated into the platform.

Developers using hema’s embedded vision platform benefit from fast hardware development and comprehensive service related to commissioning, software customization and series qualification. In the first step, users can define the interfaces and functions they require. Following this and within a very short time, hema can create a customer-specific design with the help of over 45 existing building blocks from the company’s design library.

Proprietary or even new circuits can also be integrated. Ideally, customers receive a close-to-production prototype of their electronic system in just six weeks from the time of the order. This prototype is already based on circuits that are suitable for industrial use and have been pre-tested, thus creating a perfect link between the functional prototype and the series product. In addition to rapid development, the modular design saves costs, minimizes the risk of design errors, and allows flexible product upgrades and variations.

With the prototype, customers can immediately start developing their own software applications. A Linux-based board support package is available to them for this purpose. In addition, as a Xilinx Alliance Program Member, hema offers them access to the Xilinx Kria Environment with numerous developer tools and software. Preliminary work can usually be reused on subsequent series hardware. In addition to the Kria Environment, other programs have been adapted to the platform – for example, »MuseBox«, an FPGA-based machine learning system for applications with real-time AV broadcasting from the Italian software developer Makarena Labs. At embedded world demonstrators from hema and its partner companies will show how customers benefit from customized software for embedded vision, state-of-the-art AI applications and numerous other upstream services.