Micromechanical Ultrasonic Transducers

Opening up new fields of application

Until now, it has been too expensive to develop micromechanical ultrasonic transducers for small quantities because of the high one-time costs. The advantages of these transducers could lead to completely new applications in industry and medical technology.

Micromachined ultrasonic transducers (MUTs) have been around for decades. However, in recent years they have experienced another major boom because they can be made very small and can also be used in devices that require the lowest possible power consumption. There are a wide variety of applications for these sensors, not only in the ultrasonic frequency range, but also in the audible sound range. Fingerprint sensors for use in smartphones are among the most prominent applications of ultrasound. Qualcomm is one of the largest manufacturers of these sensors in volume. They can be roughly divided into two classes: capacitive and piezoelectric MUTs, or CMUTs and PMUTs for short.

The basic principle is that a thin membrane is placed over a cavity. Sound pressure causes the diaphragm to vibrate. In CMUTs, the deflection of the diaphragm relative to a backplate is measured via the change in capacitance. The signals can be further processed in downstream electronics. Infineon's MEMS microphones, for example, which operate in the 20 Hz to 20 kHz range, are based on CMUTs.

PMUTs, on the other hand, use the piezoelectric effect and do not require a backplate as a counterelectrode. In this case, the diaphragm consists of a sandwich of different layers. These include the mechanically flexible layer on which the piezoelectric layer and the electrodes are deposited. When the layer bends under sound pressure, the piezoelectric layer generates an electrical charge. Conversely, when an alternating current is applied, the diaphragm can vibrate and generate sound.

Several piezoelectric materials can be used. The best known is PZT (lead zirconate titanate), which has a high piezoelectric coefficient. This makes it particularly suitable for actuators. The disadvantage is that this material contains lead and is therefore not RoHS compliant. However, it is indispensable in many applications, which is why RoHS exemptions continue to be granted for this material. For example, for the PMUTs, of which there are dozens in every Amazon speaker. The second drawback is that PZT has a high dielectric constant, which means that PMUTs based on it absorb a relatively large amount of energy. Because CMUTs use silicon capacitive diaphragms, they are inherently RoHS and CMOS compliant.

But PZT also has its advantages. For example, AMFitzgerald and MEMS Infinity, a new division of Sumitomo Precision Products that offers foundry services, have formed an alliance to bring piezoelectric MEMS such as PMUTs to market faster and at lower cost. Both companies see a rapidly growing market and new applications for PZT PMUTs.

A commonly used alternative to PZT is aluminum nitride (AlN) and aluminum scandium nitride (AlScN). These materials have the advantage of not containing lead. In addition, the dielectric constant is relatively low and the piezoelectric coefficient is moderate, so these sensors can be built very small. The material does not need to be polarized, so there are no aging effects due to depolarization, and it has no Curie temperature. Most interestingly, the fabrication process is CMOS compatible. In addition to PZT and AlN, the Fraunhofer-Gesellschaft also uses the AlScN variant, which has slightly better properties than AlN. However, it is more difficult to handle.

Traditional bulk transducers have often been used instead of CMUTs or PMUTs. They are usually sintered on a PZT base, then sawn and electrically bonded. It can be difficult to achieve an optimal balance between mechanical and electrical properties. Since they generate a high E-field per deformation, they should be small. However, they must be of a certain size to meet the required operating frequency. This is not possible below 4 µm. "At this point, I would like to emphasize that bulk transducers are still justified in many applications, especially when it comes to transmitting very strong acoustic signals over long distances," says Dr. Chris Stöckel, group leader "MEMS/NEMS Technologies" at Fraunhofer ENAS. According to him, potassium sodium niobate (KNN) could be a promising material as an alternative to PZT for bulk transducers, although it is still in the research phase. KNN is not yet established in cleanrooms due to its material incompatibility with many microtechnology manufacturing processes," he says.

"With our capacitive and piezoelectric diaphragms and cantilevers, we have the advantage of being able to adjust the frequencies via the geometry," explains Stöckel. Because the MUTs are structured using lithography, they can be designed very flexibly and multiplied in a scalable manner.

This opens up new perspectives for MUTs. Up to now, the market has mainly been of interest to companies developing MUTs for markets where very high volumes are required. One example is Qualcomm's fingerprint sensors used in mobile phones and laptops. This even justifies integrating the electronics into the sensors. However, even companies that sell large quantities of sensor MUTs do not integrate the electronics on the MEMS sensors, but place an ASIC next to them. For example, MEMS microphone and speaker manufacturers Vesper MEMS and Infineon do this. However, as mentioned above, Infineon, unlike Vesper MEMS, does not manufacture microphones based on PMUTs, but on CMUTs, and has no intention of switching to PMUTs, as Marc Fueldner, team leader of the MEMS concept group for microphone and pressure sensors, explained in an interview with Markt&Technik.

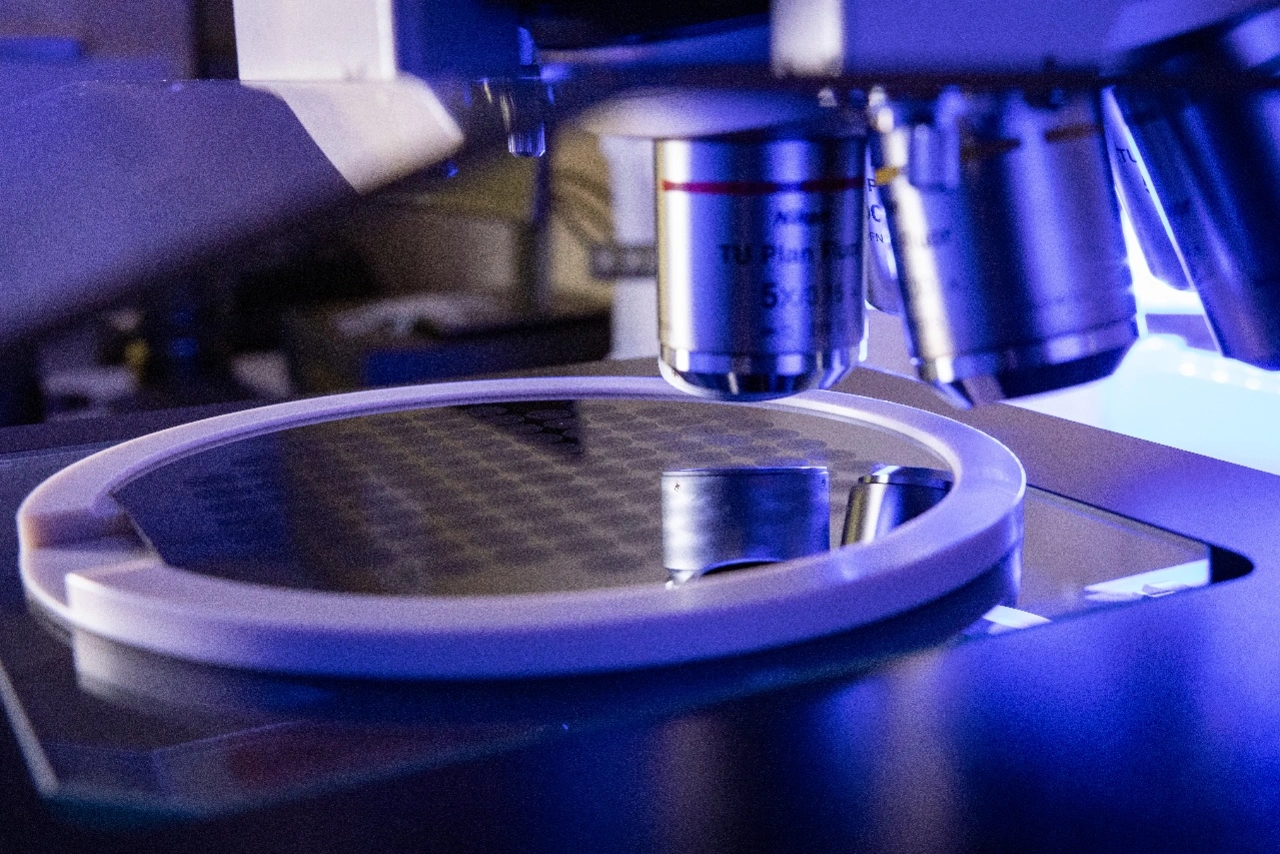

Now Chris Stöckel is convinced that the Fraunhofer Gesellschaft's Research Fab Microelectronics Germany with its research institutes ISIT, IPMS and ENAS can usher in a new era thanks to flexible manufacturing methods: "Because we can freely design the acoustic transducers in terms of geometry, electrical and acoustic properties in a wide range of applications, it is possible to make customer-specific changes with a minimum of one-off costs. The reduction in one-time costs was made possible by the introduction of adaptive MUT technology platforms based on silicon wafers. These ultrasonic transducers are manufactured in parallel on wafers with high precision and reliability using lithographic manufacturing processes, which significantly reduces unit costs for small and medium series with maximum reproducibility. In a merger of three institutes of the Fraunhofer-Gesellschaft, we have succeeded in establishing technology platforms for CMUTs and PMUTs in frequency ranges from about 20 Hz to 20 MHz for the research and development of customer-specific acoustic and ultrasonic systems.

As an example, he cites level measurement in the food industry or medical technology, which have special requirements. The measurement must be contact-free through glass or metal containers. "Our advantage here is that we can aim a large number of transducer elements at a field. Thanks to the precise, directed sound field, there is hardly any scattering and we can even get through narrow windows. With our high operating frequencies, we can increase the resolution of the systems," explains Chris Stöckel. Another example is iThera, which develops ultrasound devices based on the optoacoustic effect. So far, the company has been using special sensors from a manufacturer that specializes in bulk ultrasound sensors for scientific applications. In the future, Christian Wiest, CEO of iThera, is also considering the use of CMUTs or PMUTs and is working with Fraunhofer ENAS.

And there are many other possible applications. For example, MUTs can reduce a system's power consumption by waking it up when the sound arrives. This would work well with wireless sensor technology. PMUTs could also be used to build energy-saving speakers.

According to Stöckel, word is getting around: "Many parties have already contacted us with interest in creating systems using MUTs, indicating a growing awareness and acceptance."