What happens during an accident

Mercedes-Benz x-rays a crash test

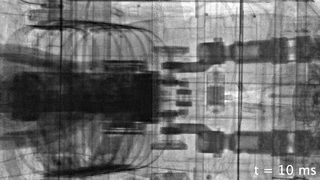

Together with the Fraunhofer Institute for High-Speed Dynamics, the Ernst Mach Institute (EMI) in Freiburg, Mercedes-Benz has carried out the world's first X-ray crash with a real car. Two dummies with female anatomy were on board on the left side facing the impact.

The technical sensation begins with a very loud bang. At 60 km/h, a device with an impact barrier rams into the orange C-Class saloon and hits it full in the side: a loud bang. Crash tests are always something special - even for the experts. But the really spectacular part of this side impact test is located in a frame on the hall ceiling above the vehicle: a linear accelerator serves as an X-ray source.

The SID IIs dummies used are test specimens with a female anatomy, specially designed for side impact tests.

Visualization of highly dynamic internal deformation processes

This technology demonstration (proof of concept) at the EMI research crash facility near Freiburg has shown that short-term X-ray technology can be used to visualize highly dynamic internal deformation processes. Previously invisible deformations and their exact processes become transparent in this way. The numerous high-resolution images allow precise analysis.

»The X-ray crash from Mercedes-Benz sets a milestone in the development tools of the future. By providing a direct view into the hidden interior, it can help to draw important conclusions for the further improvement of vehicle safety,« explains Markus Schäfer, Member of the Board of Management of the Mercedes-Benz Group and Chief Technology Officer.

»The successful X-ray crash gives us valuable insights to further optimize our technology for capturing previously inaccessible information. Fraunhofer EMI is thus consistently pursuing its strategy of using high-speed X-ray imaging to make dynamic processes visible,« adds Dr. Malte Kurfiß, Head of Crash Center, Fraunhofer EMI.

High-speed X-ray technology: up to 1,000 images per second

For several years, the Mercedes-Benz vehicle safety department has been working with colleagues at EMI on the use of X-ray technology in crash tests. The decisive factor in the breakthrough was the use of a linear accelerator with 1 kHz technology as the radiation source. The device is far more powerful than the X-ray flashes previously used in experiments: the photon energy of the linear accelerator is up to nine megaelectron volts. This means that all materials commonly used in vehicle construction can be X-rayed.

The duration of the X-ray pulse is only a few microseconds. This makes it possible to record deformation processes in the crash test without motion blur. In addition, the linear accelerator generates a continuous stream of these X-ray pulses. As a result, up to 1,000 images per second are possible. That is around 1,000 times as many as with conventional X-ray methods.

X-raying the car body from above

During the crash test, the beams illuminate the bodywork and any dummies from above. An X-ray detector is located under the test vehicle. It serves as a digital image receiver in the X-ray system: when the radiation hits the detector, an electrical signal is generated.

The intensity of this signal depends on how strongly the radiation was previously absorbed by the vehicle and dummy structure. This influences the gray value that is later visible - similar to the X-ray inspection of luggage at the airport or corresponding images taken by a doctor.

Approximately 100 still images during the impact time

During the actual impact time of one tenth of a second, the X-ray system shoots around 100 still images. Combined into a video, they provide highly exciting insights into what happens inside safety-relevant components and in the dummy's body during the crash.

In this way, it is possible to observe in detail how the dummy's thorax is crushed or how a component is deformed. Important on the way from research to industrial use: the X-ray crash does not affect any other analysis tools. The interior cameras of the crash test vehicle also record undisturbed.

The EMI experts have drawn up a comprehensive radiation protection concept for the X-ray crash. Dosimeters are used to monitor that the employees are not exposed to any radiation. The government authority has approved the operation of the facility in accordance with legal requirements. The elaborate physical protection measures include an additional 40-centimetre-thick concrete wall around the building and a radiation protection door weighing around 45 tons.

Find out what happens during the accident

»The world's first X-ray crash shows that X-ray technology can provide revealing new insights. We learn what happens inside a vehicle and to the dummies during an accident. The X-ray images also offer the opportunity to further improve the model quality of the digital prototypes,« says Prof. Dr. Paul Dick, Director Vehicle Safety, Mercedes-Benz.

Transparenter Crash in Bildern