New gas sensor technology by FaradaIC

MECS sensors follow MEMS technology

Sensors based on MEMS are ubiquitous today. The new gas sensors from FaradaIC based on MECS technology allow them to be used in completely new areas of application and can meet the increasing demand for low-cost and miniaturized gas sensors. Further advantages are described in detail here.

FaradaIC Sensors GmbH is a young company headquartered in Berlin with laboratories in Brandenburg and Serbia. After more than 20 years of combined research, Dr. Ryan Guterman and Dr. Alexey Yakushenko have succeeded in producing and implementing an electrolyte for gas sensors for the first time, which consists of a solid and thus enables many advantages in production.

Electrochemical gas sensors use electrochemical reactions on electrodes to convert chemical information into electrical signals. The electrolyte in electrochemical sensors is a crucial component because it enables ionic conductivity and supports the electrochemical reaction. Until now, the electrolytes in gas sensors have been liquid, which is why the sensors are expensive to manufacture, have a relatively large design, and only have a limited shelf life of about 1-3 years after the first calibration, even if they are not used.

The new MECS sensors can be produced cost-effectively in conventional MEMS factories, the electrolyte does not dry out even at high temperatures of 85 degrees C, the analog sensors are only about 2x2 millimeters in size and very fast.

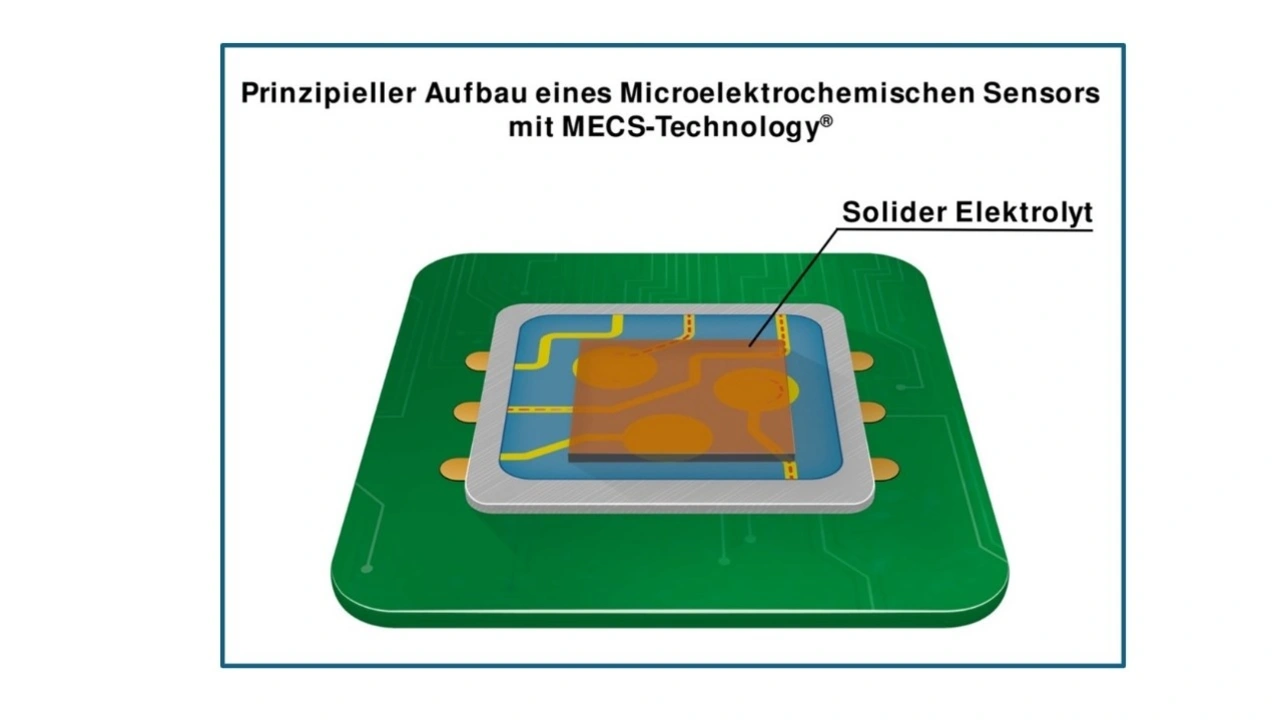

The main components of a gas sensor based on MECS technology are similar to those of a conventional electrochemical sensor, only the design is much smaller, and the sensors can be produced with MEMS processes:

- Working electrode: This electrode is the place where the electrochemical reaction of the analyte takes place. It is often coated with a catalyst that facilitates the specific reaction of the analyte.

- Reference electrode: This electrode provides a constant potential against which the potential of the working electrode. It is essential for the accurate measurement of the electrochemical potential.

- Gegenelektrode: This electrode closes the circuit and allows the current to flow through the sensor. It contributes to the reaction by performing the opposite reaction to the working electrode.

- Electrolyte: The electrolyte conducts the ions between the electrodes and provides the medium in which the electrochemical reaction takes place. Until now, aqueous solutions (e.g. KCl), organic solutions, or solid electrolytes have been used here, which are complex to produce and process.

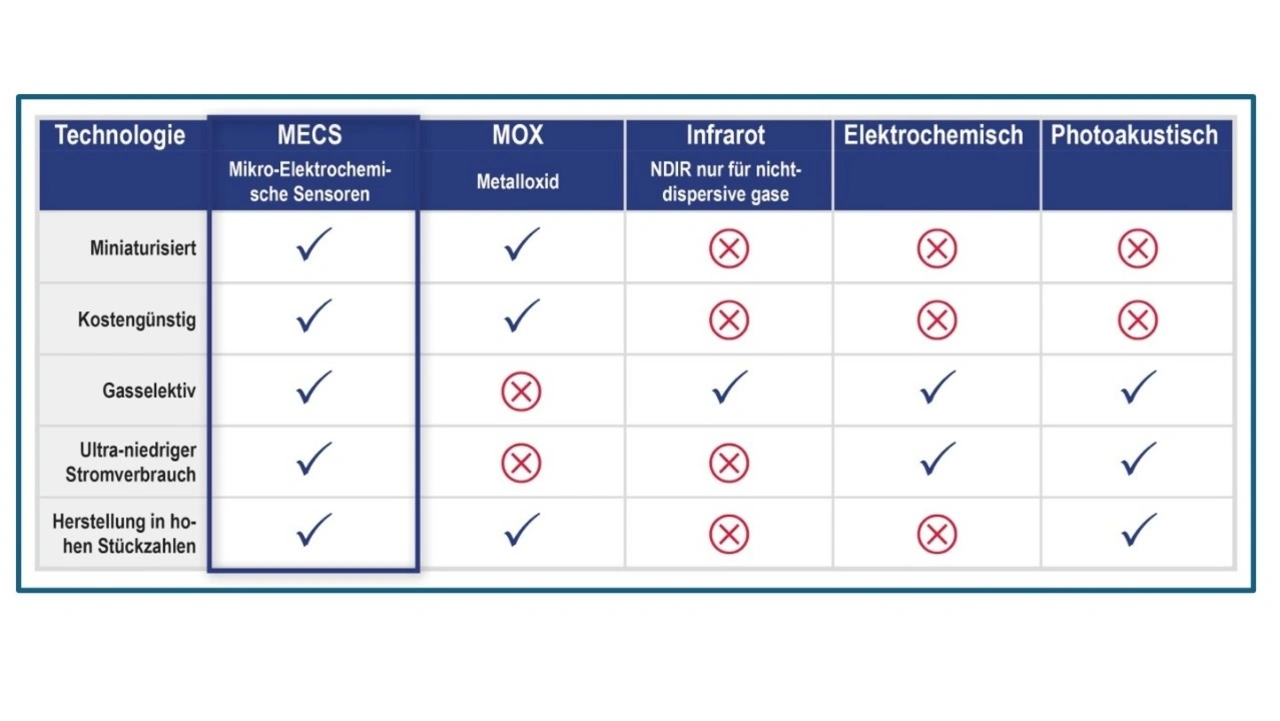

With the new materials from FaradaIC, sensors will be significantly smaller and produced in large quantities using automated processes. In addition to the dimensions, there are also other advantages over conventional technologies: A comparison with other technologies is shown in Figure 2.

All gases that can be detected today with electrochemical sensors can in principle also be measured with micro-electrochemical sensors. The developers of FaradaIC are currently concentrating on the measurement of oxygen in different concentration ranges and for different applications.

Oxygen is an important gas and essential for the survival of most living organisms. In addition, oxygen plays a central role in cellular respiration in biological systems, a process in which cells obtain energy from nutrients. Adequate oxygen levels are therefore crucial for maintaining health and well-being. In addition, oxygen is indispensable in many industrial processes, such as metal processing and chemical synthesis. Indoor oxygen levels can be affected by ventilation, occupancy, combustion, and other factors. In well-ventilated rooms, the content remains close to 21%, while in poorly ventilated, crowded or combustion-intensive rooms, it can decrease.

Values below 19.5% are considered potentially dangerous to human health. In food packaging, the natural nitrogen content can be increased from 78% to over 90%, thus reducing the oxygen concentration to less than 10%. As a result, cellular respiration slows down and fresh food has a longer shelf life.

Monitoring the oxygen content thus plays an important role in our ambient air, indoor air, protective atmosphere and many other areas.

Previous oxygen sensors usually consume a lot of electricity, are very large – too large to be integrated into food packaging and have only a limited shelf life. With MECS technology, manufacturers have the opportunity to develop small, portable and battery-powered, long-lasting IoT systems that would not be conceivable with conventional technology. In addition to the state of freshness, data can also be obtained from packaged foods in order to predict the shelf life and determine the optimal time to sell.

Additionally, the integration of IoT (Internet of Things) devices into safety technology and personal protective equipment contributes significantly to improving safety standards, especially when monitoring environments with potentially hazardous gases. Oxygen sensors, embedded in IoT-enabled personal protective equipment, enable continuous and precise monitoring of oxygen concentration in real time. These sensors can detect dangerous situations, such as lack of oxygen, at an early stage and send immediate alerts to wearers and central monitoring systems. This not only increases the safety of workers in hazardous environments, such as mines or chemical plants, but also enables a faster response to emergencies. By connecting these devices, data can be collected and analyzed to develop preventive measures and increase overall safety.

Breath gas analysis with oxygen measurement is a crucial procedure in medical diagnostics and monitoring that enables a detailed assessment of respiratory function and gas exchange in the human body. By measuring the concentration of oxygen in the exhaled air, doctors and health professionals can gain valuable insights into lung function, oxygen uptake efficiency, and overall body health. Modern breath gas analyzers are often equipped with precise oxygen sensors that enable fast and accurate measurements, providing a reliable basis for therapeutic decisions and monitoring of treatment outcomes. The measurement usually requires the wearing of a breathing mask or is limited to the measurement of the carbon dioxide change during exhalation. The small sensors based on MECS technology enable the integration into small smart devices and wearables for the first time, thus expanding oxygen sensing technology to the broad fitness and wellness market.