Fuel cell vehicles

Innovative pressure tanks for hydrogen

Can hydrogen propulsion make an important contribution to climate-neutral mobility? Prof. Dr. Horoschenkoff and his team are convinced of this. They are researching novel refueling concepts to make vehicles with fuel cells more economical.

In the future, two electric drive concepts are likely to dominate vehicle construction: the e-vehicle with battery and the e-vehicle with fuel cell powered by hydrogen. This is the opinion of Prof. Dr. Horoschenkoff from the Faculty of Mechanical, Automotive and Aircraft Engineering at Munich University of Applied Sciences.

Hydrogen is considered a promising energy carrier for climate-neutral mobility in the future. As a fuel for fuel cell vehicles, it provides the electrical energy for propulsion and is converted into water in a CO2-neutral manner. For fuel cell vehicles to become competitive with today's battery-powered electric vehicles, manufacturing costs must fall, among other things.

In cooperation with BMW, the research team at Munich University of Applied Sciences wants to place the hydrogen tank where the battery is usually located in the electric vehicle: In the underbody of the vehicle. A cuboid shape is well suited for this. The design must be able to withstand an operating pressure of 700 bar.

The challenge of the hydrogen tank

Storing hydrogen for the fuel cell in pressure tanks is technically very demanding. Currently, the integration of pressure tanks causes high losses of customer benefit and driving dynamics due to their cylindrical, bulky shape. This is where the Bryson research project, which is funded by the German Ministry of Economics, comes in. The aim of the project is to develop new types of pressurized tanks for hydrogen in automotive engineering. Munich University of Applied Sciences is involved through its Competence Center Smart Composites of the Faculty of Mechanical, Automotive and Aircraft Engineering.

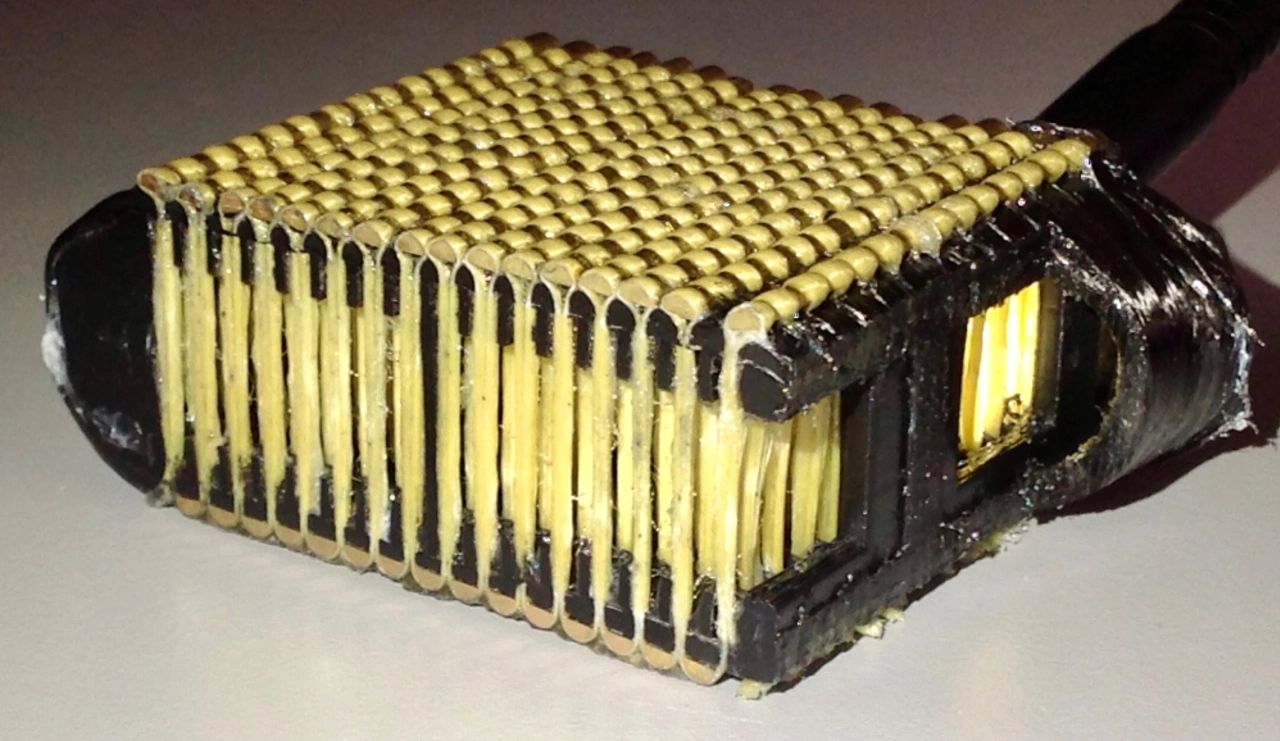

The design envisages an approximately cuboid tank geometry in which undesirable expansion of the tank is prevented by incorporated tension struts that run through the tank interior. Key challenges of the new concept are the design of the tank, ensuring tightness and developing a suitable manufacturing process. The topic of hydrogen storage in carbon fiber-reinforced tanks is not new to the team led by Prof. Dr. Alexander Horoschenkoff. Research work to increase the operational reliability of pressure tanks with special carbon fiber sensors has already been carried out successfully in the past.

Under the supervision of Prof. Dr. Alexander Horoschenkoff, 4 students of the Master of Applied Research in Engineering Sciences (Research Master) are currently working on the project. The research master, which was introduced a few years ago, enables universities to participate in larger research projects with longer durations. Initial print tests have already been carried out with construction samples.

The Bryson project has been running since December 2019 and is designed to last 3.5 years. BMW is leading the project with a total of 5 partners and total funding of over 1.7 million euros.