Biomechanics for Medicine

Heart Print: Artificial Muscles made in a 3D Printer

Swiss researchers have produced complex, soft actuators using 3D printing for the first time. The artificial muscles react to electrical impulses and are set to change prosthetics and rehabilitation. The 3D replicas can support muscles in the event of injuries or even replace entire organs.

An artificial muscle that contracts and relaxes at the touch of a button - and all from a 3D printer. Sounds like science fiction? Not for the researchers at Empa. In a groundbreaking project with ETH Zurich, they have developed dielectric elastic actuators (DEA) that can do just that.

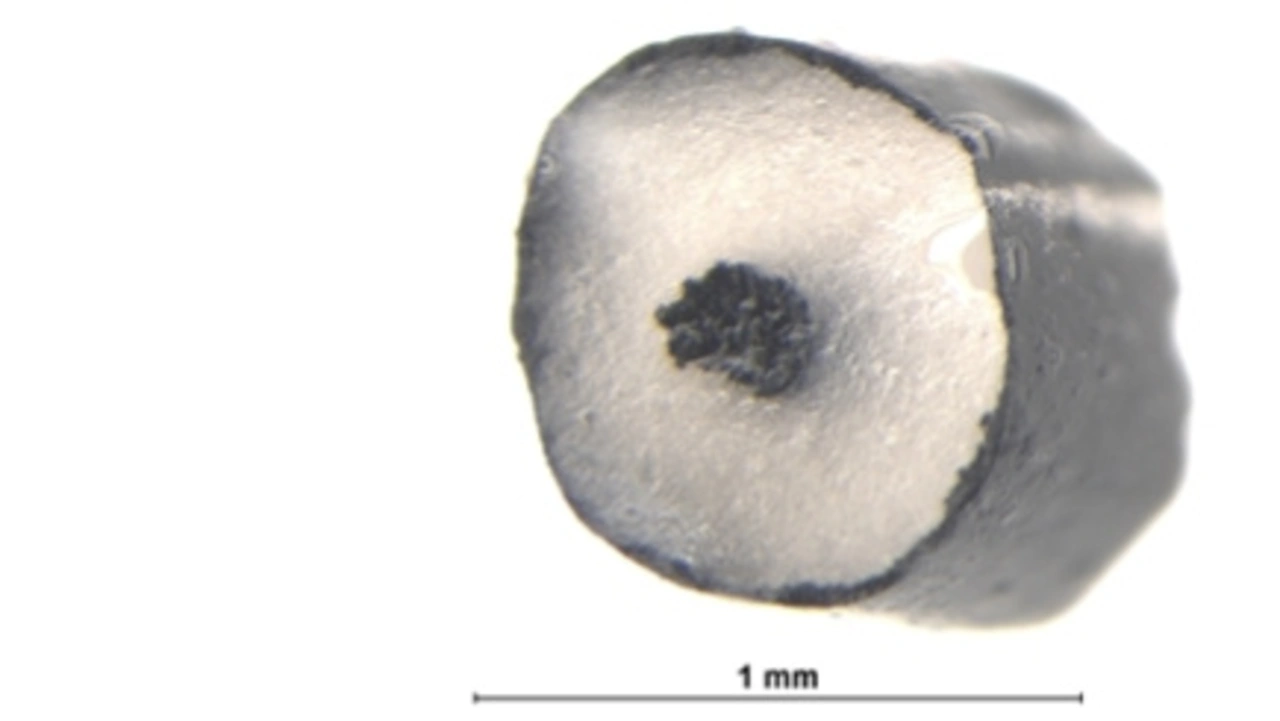

The innovative structures consist of two different silicone-based materials: a conductive electrode material and a non-conductive dielectric. The materials are bonded together in layers, similar to interlocked fingers, and react to electrical impulses like real muscles. From support for restricted movement to the possibility of printing entire organs in the future - the potential applications of the technology range from medical technology to robotics.

The Technology for Artificial Muscles

The development of these 3D-printed muscles presented the researchers with many challenges. Despite their very different electrical properties, the two soft materials had to behave very similarly during the printing process. They must not mix, but still have to hold together well in the finished actuator.

The printed »muscles« must be as soft as possible so that an electrical stimulus can lead to the required deformation. In addition, all 3D printable materials must liquefy under pressure so that they can be pressed out of the printer nozzle. Immediately afterwards, however, they must be viscous enough to retain the printed shape. Empa researcher Patrick Danner explains: »These properties are often in direct contradiction to each other. If you optimize one, three others change ... Usually for the worse.«

In collaboration with researchers from ETH Zurich, the team has succeeded in reconciling many of these contradictory properties. Two specially developed inks are printed into functioning soft actuators using a nozzle developed by ETH researchers. The artificial muscles react to electrical impulses: when an electrical voltage is applied, the actuators contract like a muscle. When the voltage is switched off, they return to their original position.

Will hearts soon come from a 3D printer?

The research is part of the large-scale »Manufhaptics« project within the ETH Domain's Advanced Manufacturing strategic area. One aim of the project is to develop a glove that makes virtual worlds tangible.

The soft actuators can also replace conventional actuators in cars, robots or industrial machines: They are lightweight, noiseless and, thanks to the new 3D printing process, can be shaped as required. If they are developed further, they could also be used for medical applications. Dorina Opris, head of the research group for functional polymer materials, is already working on this with Patrick Danner: their new process can be used to print not only complex shapes, but also long elastic fibers.

Opris even believes it is possible to print an entire heart from the new fibers in the future: »If we manage to make them a little thinner, we can get pretty close to how real muscle fibers work.« (uh)