Forschungszentrum Jülich

Fast-Charging Solid-State Batteries

Solid-state batteries are much safer as lithium-ion batteries, because they contain no liquid parts that could leak or catch fire. But they are not fast-chargeable. Jülich scientists have introduced a concept that allows charging and discharging currents up to ten times higher as previously.

There are currently great hopes for solid-state batteries. They contain no liquid parts that could leak or catch fire. For this reason, they do not require cooling and are considered to be much safer, more reliable, and longer lasting than traditional lithium-ion batteries. But the low currents during charging and discharging are considered one of the biggest hurdles in the development of solid-state batteries. It usually takes about 10 to 12 hours for a solid-state battery to fully charge. That is far too long for practical use.

Scientists at the Jülich Institute of Energy and Climate Research (IEK-9) have now introduced a new concept that allows currents up to ten times greater during charging and discharging than previously described in the literature. The new cell type takes less than an hour to recharge. The improvement was achieved by a “clever” choice of materials with a focus on consistently good compatibility. All components were made from phosphate compounds, which are well matched both chemically and mechanically.

In conventional lithium-ion batteries, a liquid electrolyte is used, which usually contacts the electrodes very well. With their textured surfaces, the electrodes soak up the liquid like a sponge, creating a large contact area. In principle, two solids cannot be joined together seamlessly. The contact resistance between the electrodes and the electrolyte is correspondingly high.

“In order to allow the largest possible flow of current across the layer boundaries, we used very similar materials to produce all components. The anode, cathode, and electrolyte were all made from different phosphate compounds to enable charging rates greater than 3C (at a capacity of about 50 mAh/g). This is ten times higher than the values otherwise found in the literature,” explains Dr. Hermann Tempel, group leader at the Jülich Institute for Energy and Climate Research.

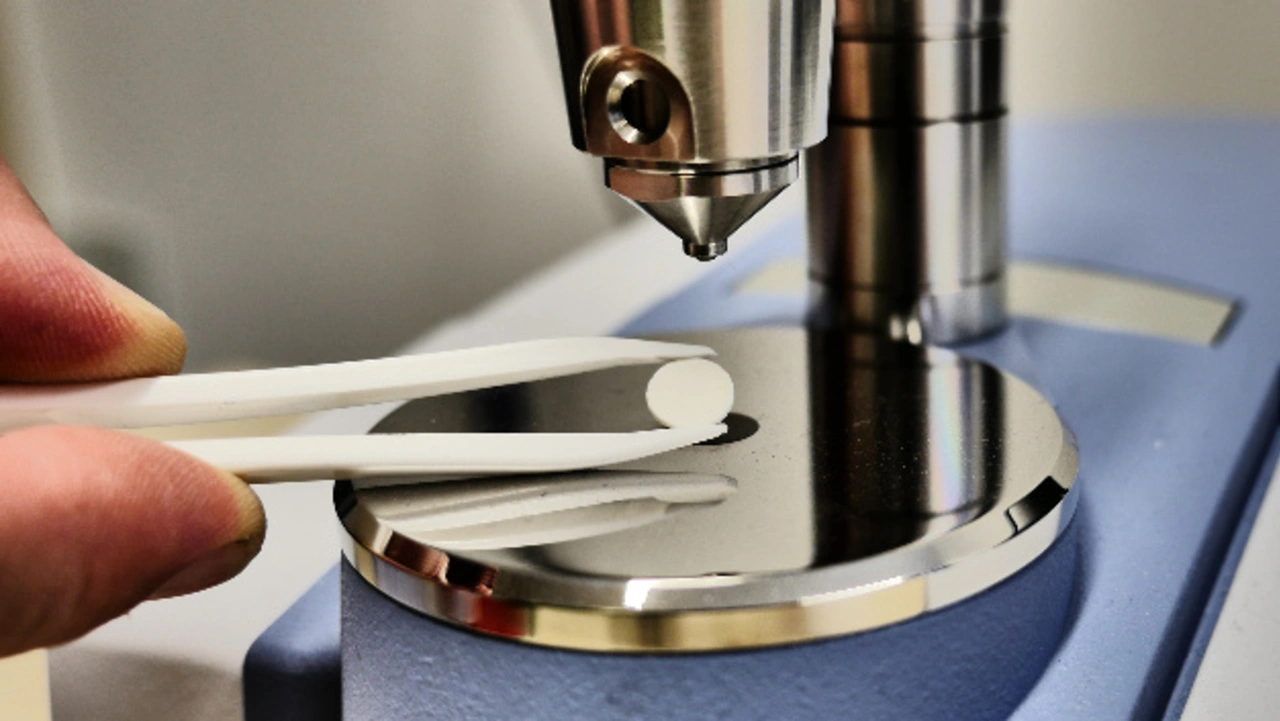

The solid electrolyte serves as a stable carrier material to which phosphate electrodes are applied on both sides using the screen printing process. The materials used are reasonably priced and relatively easy to process. Unlike conventional lithium-ion batteries, the new solid-state battery is also largely free of toxic or harmful substances.

Applications in Electric Cars and Smart Home

“Initial tests show that the new battery cell is very stable over 500 charge and discharge cycles and retained over 84 percent of its original capacity,” said Dr. Shicheng Yu. "There is still room for improvement here. Theoretically, a capacity loss of less than 1 percent should even be feasible," said Yu, who developed and tested the battery as part of a China Scholarship Council (CSC) funding programme at the Jülich Institute for Energy and Climate Research.

Institute director Prof. Rüdiger-A. Eichel is also convinced of the advantages of the new battery concept. “The energy density is already very high at around 120 mAh/g, even if it is still slightly below that of today’s lithium-ion batteries,” says Eichel. In addition to the development for electromobility, the spokesman for the “battery storage” topic in the Helmholtz Association believes solid-state batteries will also be used in other areas in future: “Solid-state batteries are currently being developed with priority as energy storage for next-generation electric vehicles. But we also believe that solid-state batteries will prevail in other fields of application that require a long service life and safe operation, such as medical technology or integrated components in the smart home area,” says Eichel.

Original publication:

Shicheng Yu, Andreas Mertens, Hermann Tempel, Roland Schierholz, Hans Kungl, and Rüdiger-A. Eichel, Monolithic All-Phosphate Solid-State Lithium-Ion Battery with Improved Interfacial Compatibility ACS Appl. Mater. Interfaces (published online June 12, 2018), DOI: 10.1021/acsami.8b05902