Infrastucture in Commercial Buildings

Fail-Safe Wireless IoT Network with IP500

The wireless IoT standard IP500 creates a redundant infrastructure in addition to the robust and high-performance networking of sensors and actuators in commercial buildings. This meets the high availability requirements of security applications that previously only wired infrastructures could meet.

Transferred to IoT applications, the sports car becomes the data package of an IoT sensor, and the road represents the IoT infrastructure. The sports car example illustrates how an IoT network and an IoT infrastructure must be set up and operated to ensure secure and fast data communication for IoT applications in commercial buildings.

If roads are compared with airways, the difference between wired and wireless communication becomes clear.

For use in security-critical environments, such as access control, intrusion, and smoke alarm systems, only wired infrastructures have been approved according to the VdS standard »Class B« or even »Class C« (bank building).

In addition, wireless-based, proprietary security systems that have been developed at great expense are occasionally offered. Their range of applications, which is limited to a few functions, only provides a low level of data security and networking performance of the individual wireless link.

Wired Networking Versus Wireless Networks

Networking communication in commercial buildings with cables has a long tradition and is considered safe and reliable – which is true to a certain extent.

When looking at the installation costs and the flexibility of the networking as well as the connection of sensors and actuators in new buildings and especially in a retrofit installation, it quickly becomes clear that there are limits to wired networking. Are innovative IoT applications or needs of a building operator taken into account in this consideration, i.e. with regard to the active mobility of people and assets – mobile workstations, autonomies transport vehicles (AGV, Automated Guided Vehicle) or robots – such IoT applications can only be implemented with wireless network communication.

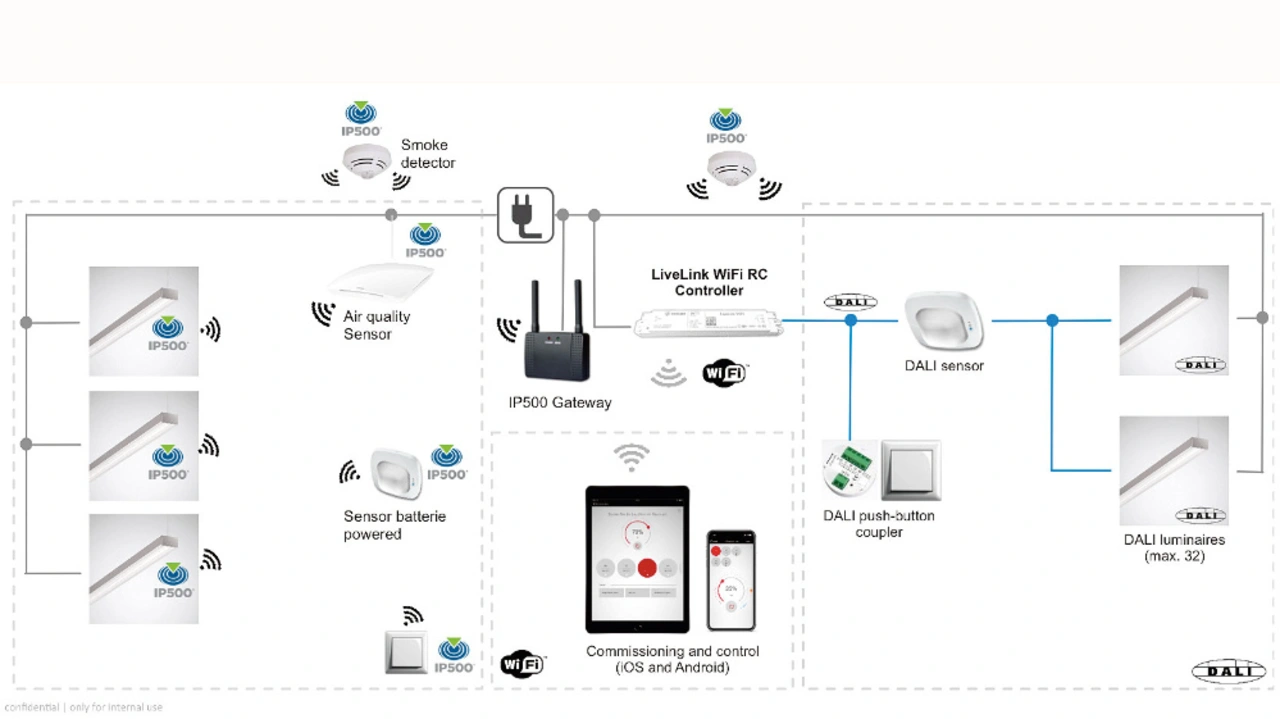

The solution for networking all IT and IoT components in a building will ultimately be a combination of wired and wireless-based networking of control data. The example of a lighting application in Figure 1 illustrates this combination of wired installation of existing sensors and actuators on a DALI basis and retrofitting with an IoT wireless network. By networking the sensors via a wireless network based on an open standard, the respective sensor data can be distributed interoperable to various control devices or control units in other applications, i.e. HVAC (heating, ventilation, energy valves, air condition systems) or access control.

Secure and Robust IoT Wireless Networks

A wireless-based IoT networking of sensors and actuators in commercial buildings has so far not been possible on a large scale. The reason for this was that certain requirements had to be addressed first so that an IoT wireless standard could offer secure, robust, and powerful wireless network capabilities. At the same time, the wireless standard should be open and scalable and correspond to the security standards. Security, robustness, and redundancy in an IoT wireless network can be divided into three levels:

- The physical wireless level – with properties such as frequency, band, and modulation method, i.e. standardized by the IEEE.

- The networking level - with the network topology, routing, and encryption.

- The infrastructure of an IoT network – with gateway and database structure, repeaters and wired devices, i.e. Switches.

The first two points have already been presented in detail in specialist articles [1, 2]. In an IoT wireless network, several – at least five – performance factors and security mechanisms must always be met at the same time so that the wireless network as an IoT platform for use in commercial buildings achieves a high level of acceptance. This was confirmed for the IP500 wireless standard by the pre-conformity of the VdS (formerly »Verband der Sachversicherer e.V.«, today: VdS Schadenverhütung GmbH, subsidiary of the German Insurance Association (GDV)) according to the EN50131-5-3 standard. The main factors of this certification include:

Dual-band capability and OQPSK modulation (Offset Quadrature Phase-Shift Keying) for high robustness.

- Use of the sub-GHz band for high wireless penetration and range in buildings.

- Asynchronous meshing and routing algorithms with a short latency period of less than 50 ms for the transmission of sensor data to the control unit and back.

- High bandwidth / data rate with low energy requirements to achieve a long battery life.

- High scalability and security through cryptography and AES128 encryption in the wireless network and in handling the network keys.

IP500 – Tested for Heart and Kidney

In extensive tests under real conditions, the companies DAFÜR (Darmstadt, Germany) and umlaut (Aachen, Germany), together with the Leipzig University of Technology, Economics and Culture (HTWK, Leipzig, Germany), have tested theses most critical requirements.

The test results have shown that the IP500 standard as an IoT wireless platform combines and fulfills these MAIN requirements: security, robustness, and high performance.

Range and Latency in Real Environmental Conditions

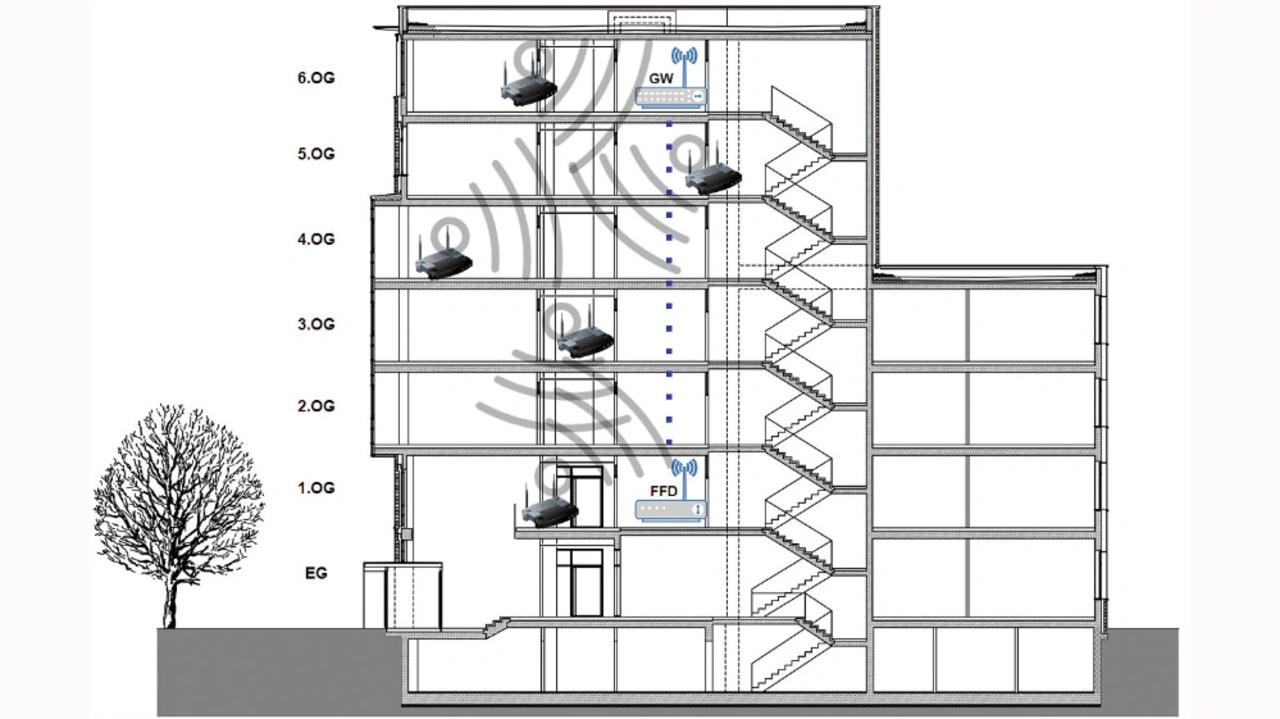

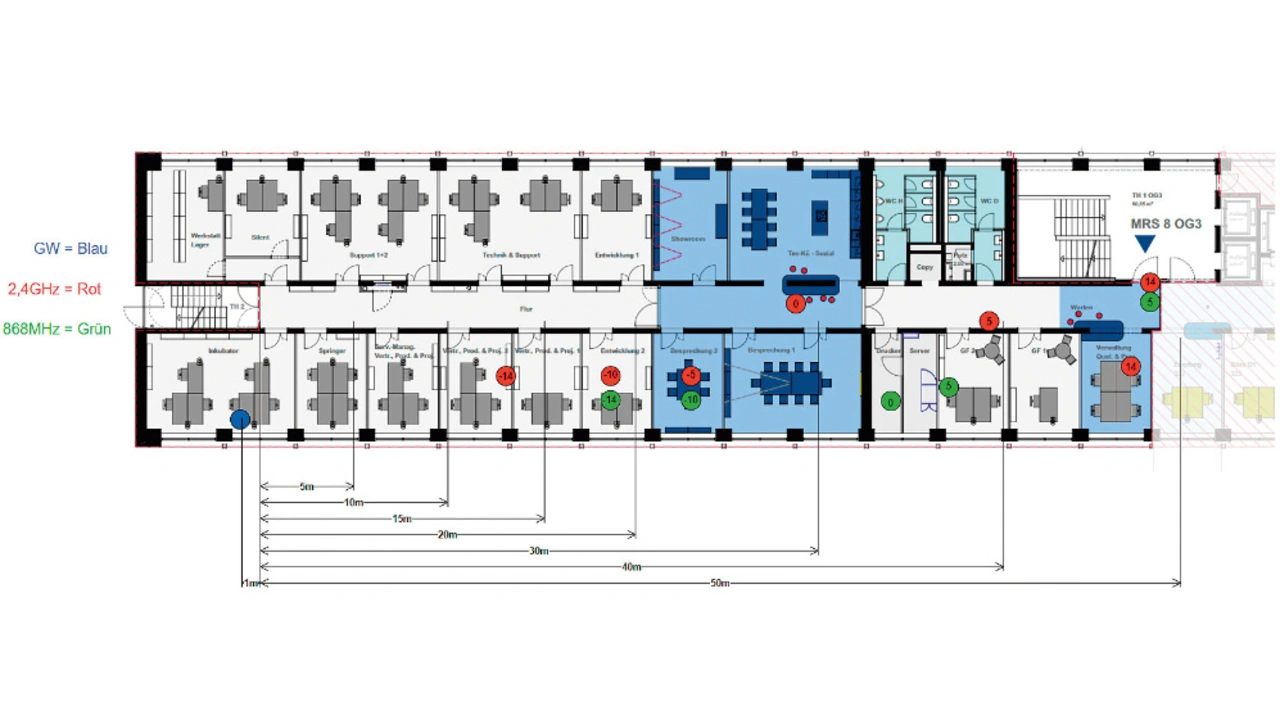

In tests carried out by DAFÜR, the transmission range of a sensor was measured vertically over several floors and horizontally in office floors to the gateway. The test parameters, including the interference from Wi-Fi and sub-GHz components and the building dimensions, correspond to a real office environment.

The result shows that the range of direct wireless communication between the gateway and the sensor (end device) extended to more than six (6) floors – see Figure 2

The range in out-door test were shown results between 600 and 1,200 m could be achieved, depending on the frequency band. In tests both indoors and outdoors, data rates of 100 kbit/s (sub-GHz) and 250 kbit/s (2.4 GHz) were determined.

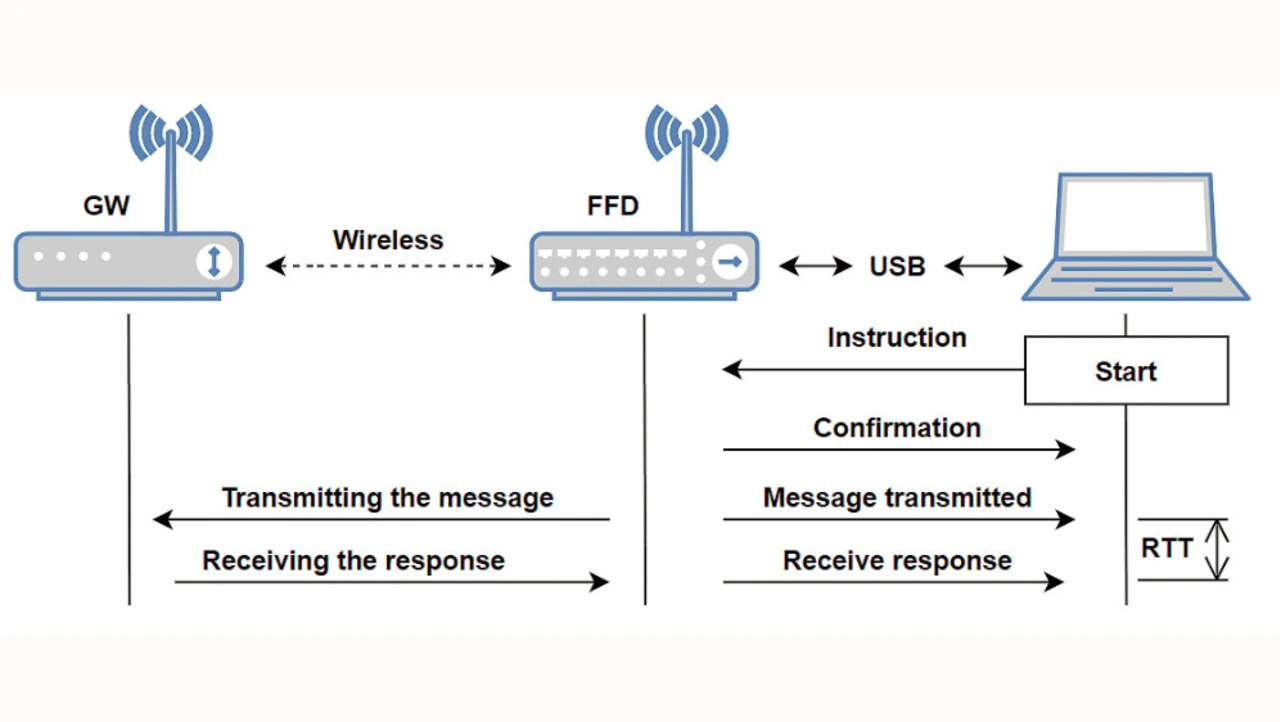

The routing of the IP500 network was tested in a further test step. It should be determined whether the latency of one or more nodes in the meshed network remains below the limit of approx. 50 ms.

A short latency period is particularly important to handle time-critical applications such as lighting solutions or access controls can be controlled via the wireless network. In this test too, the IP500 network delivered outstanding measurement results.

The time per node was measured at 11 ms. In the case of data transmission over several nodes, the total time corresponded to 11 ms multiplied by the number of switching nodes in the communication path. Figure 4 shows the measurement setup used by DAFÜR for this measurement.

Measuring Robustness in an Industrial Environment

The robustness of an IoT wireless transmission is of enormous importance, just like the road surface (motorway or dirt road) for the sports car from the introductory example, so that it can develop its performance.

The company umlaut examined the IP500 standard and carried out a stress test in a very demanding environment.

Such difficult conditions for wireless networks are often found in industrial environments, in production halls, but also at trade fairs – where more than 100 hotspots are actively transmitting, in vehicles, ships or aircraft. In these environments, other wireless standards also transmit data streams, i.e. Wi-Fi, Bluetooth, etc. In addition, there are machines in industrial halls that generate uncontrolled interference signals (EMI).

Umlaut chose a metal-insulated aircraft cabin as a test environment and had 40 smartphones continuously transmit voice data with Bluetooth and Wi-Fi routers – see Figure 5.

The selection of the test parameters corresponds to a real interference environment with data streams (streaming), as is often found at trade fairs, in aircraft or in an office environment.

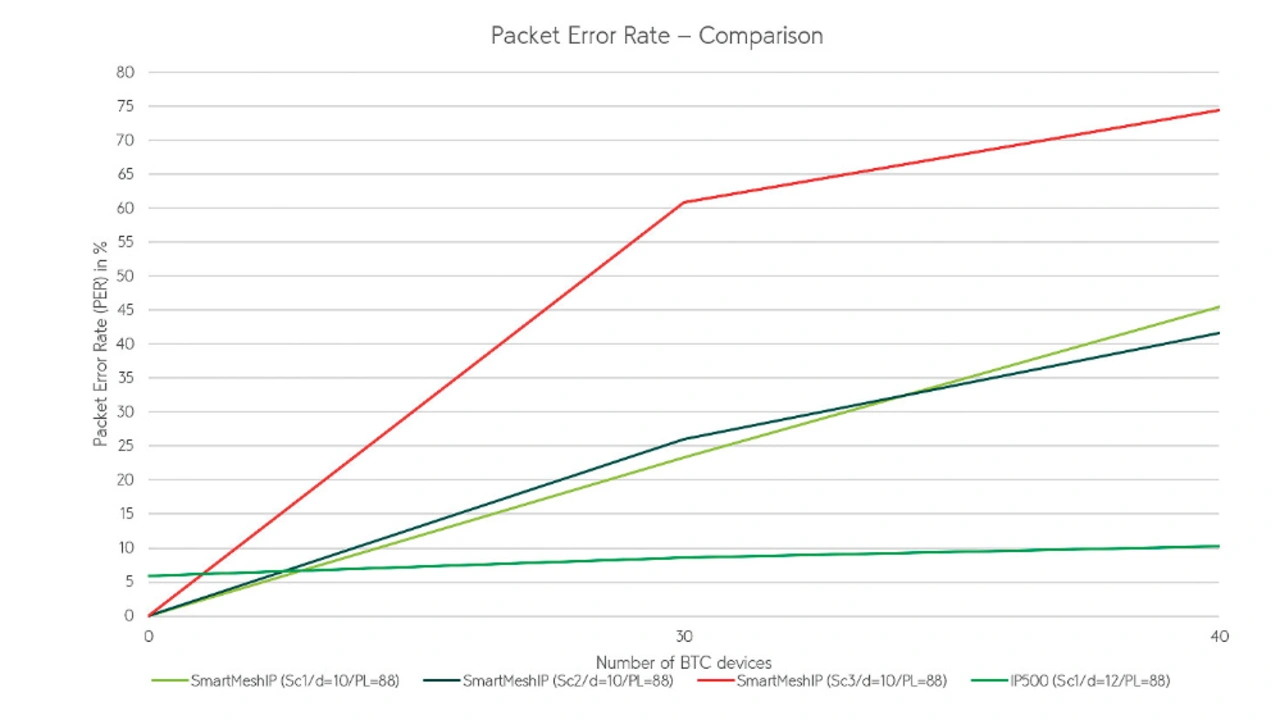

- Every 100 ms, 88-byte packets were sent over the wireless network under test.

- The distance between the transmitters and receivers of the wireless network to be examined was 12 m in direct connection.

- Three Wi-Fi interference scenarios were defined with different channel occupancy - i.e. 70-70-30 for channels 1, 6 and 11.

The target was set at 3000 successful packet deliveries. In addition to IP500, other wireless standards were included in the test – LoRa, BLE and SmartMeshIP. The frequency for testing the wireless standards was set at 2.4 GHz. As a reminder: The IP500 standard can switch in real time / automatically to another band in the dual band method depending on the disturbances - and that for each node and individually in a meshed network.

In order to be able to compare the robustness of IP500 with the other four wireless standards, the IP500 network was also limited to the 2.4 GHz frequency. If the full dual-band capability of the IP500 standard is used, the IP500 network would dynamically switch to the free band in the event of current (local) interference fields. This asynchronous meshing (routing) with the dual-band capability makes the IP500 network a wireless network with extremely robust wireless network communication.

The results of the tests show that the IP500 wireless network has by far the best packet error rate (PER, Packet Error Rate) of all tested wireless networks with an increasing number of sources of interference (Figure 6).

This robustness also convinced VdS and made the IP500 standard as the only IoT wireless platform pre-conformity for the transmission of data from security applications in commercial buildings.

Secure and Redundant IoT Wireless Infrastructure

Last year, the IP500 Alliance presented the first prototype of a redundant IoT wireless infrastructure at the Wireless Congress 2019 and CES 2020, Las Vegas. The demonstration included intelligent database management of the IP500 infrastructure, through which the sensors automatically switch seamlessly to the nearby IP500 Gateway if one or more IP500 Gateways fail. In the wireless network, IP500 Gateway can also be installed redundantly so that a failure of an IP500 Gateway can be compensated for by a neighboring IP500 Gateway that takes over the communication.

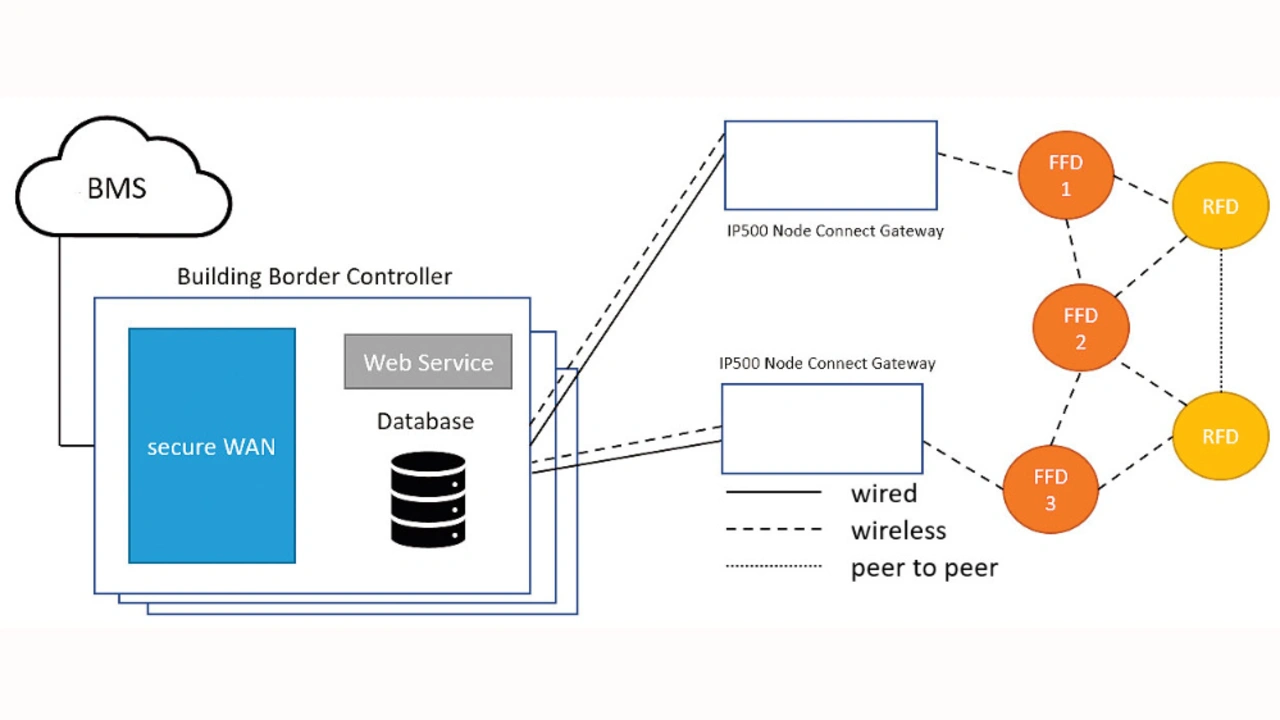

The company DAFÜR is currently developing the IP500 Network Orchestrator (NO) as a link between internal building communication and external services, which can be available locally or in cloud structures.

In addition to IP500, the NO also combines other building communication standards such as BACnet, DALI and other IoT standards in a manufacturer-independent, open system to ensure a secure and highly available connection.

Thanks to quorum technology, the reliability of the redundant NO is so high that even the failure of several routers – i.e. 2 out of 5 or 3 out of 7 – has no effect on functionality.

The Building Management System (BMS) takes over the visualization of the IP500 network and can be operated locally or in the cloud. It controls the network components and receives data from sensors as well as from the network itself via redundant and secure communication interfaces of the NO (Figure 7)

This combination of cost-effective IP500 Gateways with high-quality NO cost-effective and scalable installation of IP500 networks in buildings of all sizes.

Such a secure, redundant, and scalable IoT architecture enables the interoperable networking of all security and comfort applications in a single IoT network infrastructure – see [2].

Certified Robustness

IoT products in commercial buildings require a secure, robust and powerful wireless network. All three levels – radio, network and infrastructure – must meet high requirements. The system must be able to be fully interoperable in accordance with the established regulations and at the same time withstand real disturbances such as absorbing and reflecting walls or the failure of infrastructure components. Weak points on one of these levels lead to a risk for the operator or user in professional operation.

The redundant structure of the IP500 infrastructure ensures that the sensor networks are highly reliable. The IP500 standard has been certified by the VdS as the most robust IoT radio network. Globally successful market leaders in building technology have now accepted IP500 as the safest and most robust IoT wireless IoT platform and have begun to integrate the technology into their product portfolios.

Literature

[1] Adamski, H., Gisbrecht, W.: Secure and reliable Wireless Networking – The IoT Revolution for commercial Buildings. elektronik.de, 11.2.2020, https://www.elektroniknet.de/international/the-iot-revolution-for-commercial-buildings.173266.html.

[2] Knödler, P.; Konrad, F.: Comfort and Safety Combined – IoT Wireless Platform for Commercial Buildings. elektronik.de, 8.6.2020, https://www.elektroniknet.de/international/iot-wireless-platform-for-commercial-buildings.177132.html.

The Authors

Christian Varga

studied electrical engineering with a specialization in communication technology (B. Sc.) and then industrial engineering (M. Sc.) at the Darmstadt University of Applied Sciences. He works as a product manager at DAFÜR and is responsible for the Building Border Controller (BBC) as Product Owner.

christian.varga@dafuer.com

Vladimir Rakic

studied electrical engineering with master in communication technology (M. Sc.) at the Faculty of Belgrade. Initially for over six years he was responsible for planning and optimizing the mobile network of one of the leading Austrian mobile network providers. He has been with umlaut for over seven years and has been responsible for IoT as Head of IoT since 2019.

In this area he worked successfully on various projects with utility companies (smart metering, payment, smart cities, etc.), suppliers of IoT telecommunication modules, mobile network operators, IoT device manufacturers and chipset manufacturers.

vladimir.rakic@umlaut.com