MEMS loudspeakers

CMOS compatible electrostatic transducers

Micro loudspeakers, buried in the CMOS chip, should enable even smaller, more powerful and particularly energy-efficient in-ear wireless headphones. For the commercialization of the patented technology, a spin-off of the Fraunhofer IPMS has now convinced investors to provide initial financing.

Arioso Systems GmbH received EUR 2.6 million from investors for early financing (seed). The company is a spin-off of the Fraunhofer Institute for Photonic Microsystems IPMS in Dresden, and is one of the first companies worldwide to offer CMOS-compatible technology for MEMS sound transducers. It is now financially supported by Brandenburg Kapital, Potsdam, the High-Tech-Gründerfonds III, Bonn, the Technologiegründerfond Sachsen, Dresden, and Business Angels.

Silicon sound transducer for earphones

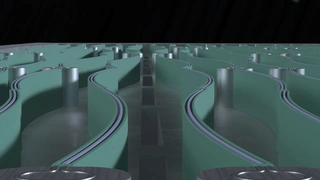

Arioso Systems aims to bring to market MEMS transducers that can be manufactured using standard CMOS manufacturing technology. These micro loudspeakers are based on electrostatic bending actuators (NED – Nanoscopic Electrostatic Drive) developed at Fraunhofer IPMS.

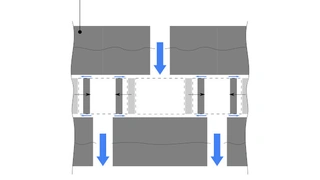

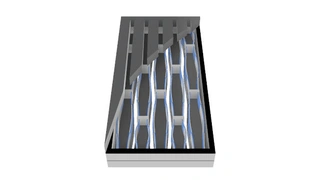

The new MEMS sound transducer does not have a membrane like conventional loudspeakers, but many bending actuators – similar to the strings of a harp. They are only 20 μm thin and are located inside a Si chip. Openings at the top and bottom of the chip – at right angles to the movement of the bending beams – allow air to escape from the chambers and flow into the chambers where the electrostatic bending actuators move.

MEMS transducer

In the bending actuators, electrode gaps as thin as 200 nm generate enormously high forces through electrostatic fields with the aid of a control voltage, the audio signal. These forces lead to a curvature of the bending beam and the mechanical movement of the "string" in the transducer.

Due to the drive principle, the deflection of the NED actuators is much greater than the electrode gap. Therefore large deflections can be generated with low control voltages. With suitable electrodes and an arrangement of the actuator cells on both surfaces of the bending actuator, movement in both directions (bidirectional) is possible.

Since the NED actuators can be integrated directly into the silicon chip, they take up very little volume and are much more energy efficient than conventional loudspeakers. They make it possible to build extremely small micro loudspeakers, e.g. for in-ear headphones and hearing aids.