Interview with Philipp Wallner

Agile development in mechanical and plant engineering

Modern production plants are becoming increasingly complex. This is also reflected in the software code. Good tools are therefore essential for development. Philipp Wallner explains how MathWorks supports companies and manufacturers.

Mr. Wallner, Mathworks would have had a booth at SPS 2021 again. What would you have shown there?

Philipp Wallner: The focus is on simulation and data analysis based on our development software Matlab and Simulink. At the booth, we would have shown how mechanical and plant engineering can successfully use tools - for example, for model-based development or for evaluating machine data.

The topic of simulation is not new in industry. Why do you think it is especially important now for machine builders to deal with simulation models?

Over the last few years, modern production plants have become increasingly complex. One driver for this is the requirement for increasingly flexible production. Here, the complexity primarily concerns the software - and more specifically, the software that runs on an industrial controller, for example a PLC, on the machine. To develop and validate the function of the software, methods of model-based development are increasingly coming into focus.

What about retrofitting software on the machine during operation?

This is a key point: If the electromechanical basis of the machine remains more or less unchanged in the future, manufacturers will be constantly retrofitting new functions on the software side. For this purpose, model-based development must be used to ensure in advance that the machine executes the new function without errors. As soon as the developer has tested the new software in the simulation, he transfers it to the PLC or the industrial PC by means of automatic code generation - i.e. directly from the development process into the running operation.

That sounds a bit like DevOps - is it true?

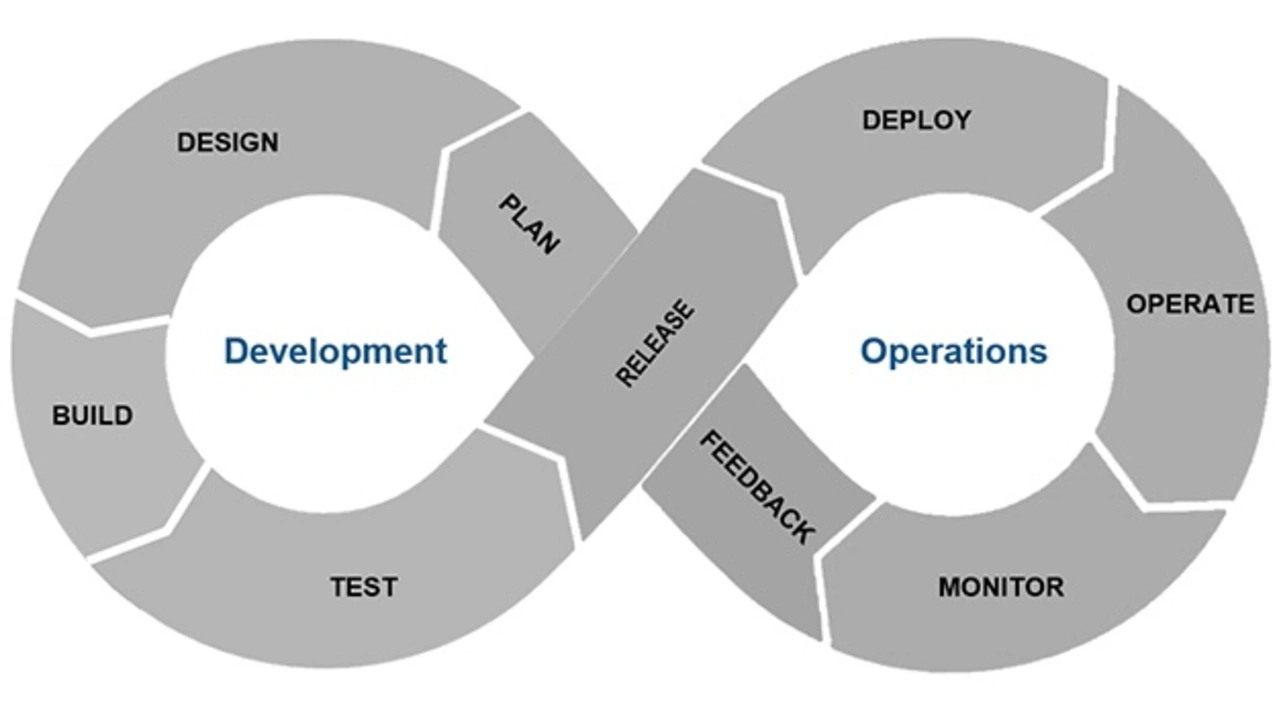

Yes - in the field of IT software, DevOps for agile development has been established for years. A developer continuously transfers the software building blocks directly from development to operations. Feedback from operations is then fed back into the development process. We think DevOps based on simulation models - i.e. 'Model DevOps' - is helpful for developing and continuously expanding IT software on the one hand, and for complex mechatronic systems such as product in-machines on the other hand.

That sounds exciting - but somehow like a dream of the future...

Not necessarily. Leading industrial companies such as Krones or Atlas Copco are already using simulation models in the form of digital twins throughout the machine life cycle. This enables them to develop new tested functions in a short time and bring them into operation.

What role does MathWorks play in this?

Developers use our software to efficiently develop and test new machine functions. For example, Matlab, Simulink, and over 100 toolboxes to automatically generate C, C++, or IEC 61131 code, create OPC UA connectivity, or for predictive maintenance applications. In addition, our technical contacts in Germany and other locations worldwide have experience from numerous customer projects in different industries. With this, we can support machine builders on their way to digital transformation.