Rajesh Vashist, CEO of SiTime

»5G will be a Game Changer for MEMS Oscillators«

Still the vast majority of all timing solutions are quartz-based. A company that is determined to change that to semiconductor-based solutions is SiTime. And 5G infrastructure will be the game changer, believes Rajesh Vashist, the CEO of SiTime. We met him at electronica.

I read that some of the first quartz oscillators were built in the late 1920s at Bell Labs. Can you tell me a little bit on the history of the MEMS oscillators?

Rajesh Vashist: Because of the limitations of quartz oscillators and the promise of MEMS, researchers began developing MEMS oscillators in the middle of the 20th century. The first MEMS resonator was built in 1967 at IBM. Various companies looked into building silicon MEMS-based timing devices in the 1990s.

What was the issue?

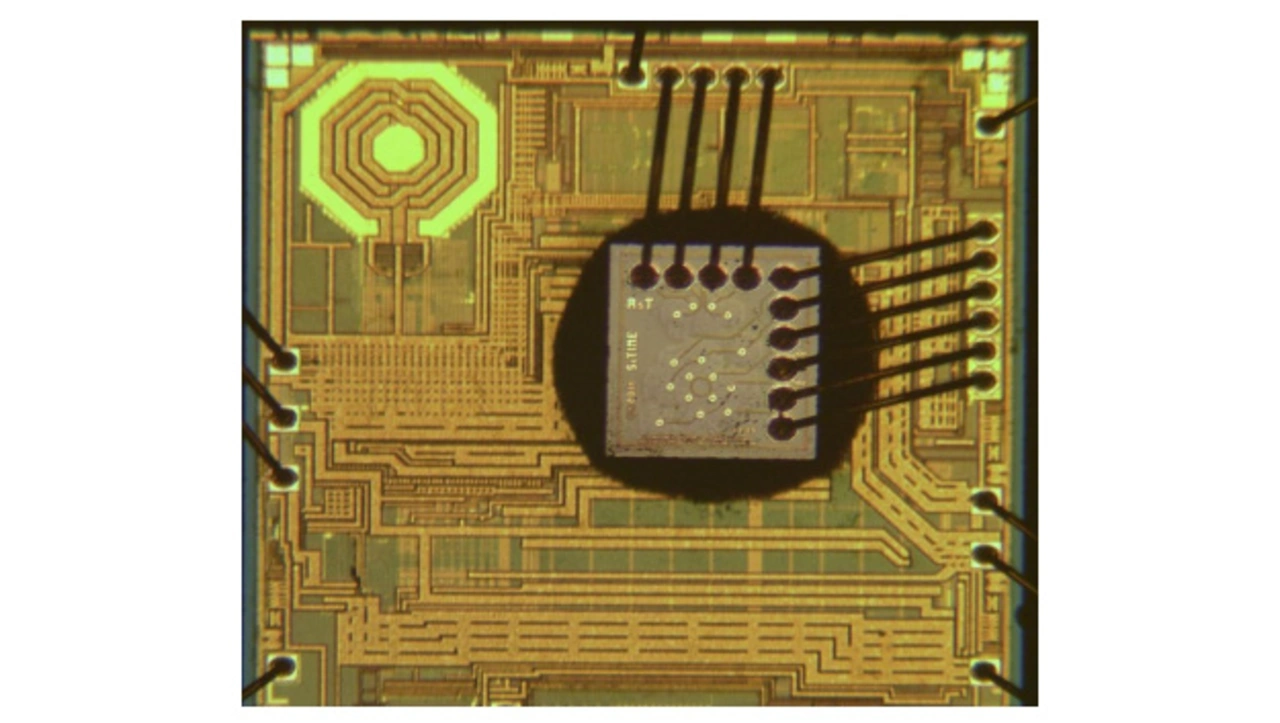

Well, nobody could get a handle on temperature stability during this time. In 2006 SiTime introduced the first successful production-worthy MEMS resonator. Our technology focused on using single-crystal silicon, which is a pure, highly predictable, and inexpensive material. Together wit Bosch, our original mother company, we invented the MEMS First and EpiSeal processes to manufacture resonators with the highest quality and reliability.

Shortly after SiTime’s announcement, Discera (now a part of Microchip; editor’s note) also introduced a MEMS resonator. From 2006 to 2012, several companies including Silicon Labs, IDT, Analog Devices, Maxim, and NXP spent over 500 million dollars to develop MEMS resonators.

In the past decade, SiTime has improved frequency stability 5,000 times, jitter 800 times, and Allan deviation 30,000 times. To date, we do not see any technological barriers to our MEMS technology and we expect to continue to innovate at this rapid pace. Today, SiTime offers MEMS OCXOs, super-TCXOs, oscillators, and resonators. SiTime has the largest team that is completely focused on timing.

What are the drawbacks of quartz oscillators?

There three main issues: dynamic performance, reliability, and the supply chain.

Dynamic performance is the capability to maintain high performance under harsh and changing environmental and system conditions. This parameter is critical for many applications such as 5G. Quartz oscillators, however, cannot handle dynamic conditions like vibration, shock, and rapid temperature changes. Since our MEMS resonator has only a very low mass, such influences hardly disturb it.

Reliability is also an issue for quartz devices. Their MTBF is between 100,000 and 30 million hours. Our MTBF is typically over 1.5 billion hours. This is very important for high performance systems such as core telecom infrastructure and automotive that will remain in the field for long periods of time.

One last area of concern for quartz devices is their supply chain which is geographically concentrated. Kyocera, a quartz vendor, also supplies approximately 80 percent of the world’s ceramic packages. If there is an issue or natural disaster at their manufacturing location, such as the 2011 Tsunami in Japan, it could disrupt the entire quartz supply chain. SiTime uses the semiconductor supply chain and in most cases standard plastic packages that are available from multiple suppliers.

Unlike quartz companies, we have expertise in MEMS, analog, compensation algorithms, and packaging – and we use all this proficiency to deliver the best solution to the customer. Quartz companies typically outsource the analog and packaging so they cannot innovate as fast and provide as good of a solution as SiTime.

What are the drawbacks of MEMS oscillators? What about price and yield?

From a technical point of view, there are no limitations or drawbacks. The biggest challenge is that customers need to know that such devices are available. Today we have 10,000 customers, but there are 150,000 potential customers that could use our products.

Since quartz timing has existed for 90 years, quartz companies have developed many more types of products than currently exist with MEMS timing. For example, quartz companies offer standalone resonators, which we are in the process of developing. We do not yet offer mobile TCXOs. However, over time, our timing products will cover the entire market.

Regarding price and yield we are very competitive. Our MEMS yields are in the 90 percent range.

SiTime was founded in 2005 by a couple of Bosch employees. Why did these people develop MEMS oscillators on their own and not within Bosch?

Bosch is focused on automotive systems and electronics. While we cannot speak for Bosch, we believe that our founders achieved agreement with Bosch management to start an independent company focused on MEMS timing technology. Bosch invested in SiTime and played an instrumental role in our progress. They held a board seat and helped us with manufacturing. We have recently announced a strategic partnership to address the 5G, automotive, and IoT markets. SiTime will work with Bosch to develop processes for next-generation MEMS resonator products.

As far as I know is Bosch one of the foundries you use, isn’t it?

Actually, Bosch is our preferred MEMS manufacturing partner. Bosch has been manufacturing MEMS resonators for us since 2009. During this time, Bosch has developed new process technologies that have helped enhance SiTime timing solutions. Bosch’s outstanding manufacturing and supply capabilities has helped SiTime ship over a billion units while we sustained excellent quality.

Our recently established strategic process technology partnership with Bosch is aimed at accelerating innovation in MEMS timing. This partnership extends our relationship with Bosch to develop new process technologies for future MEMS resonators. This arrangement will utilize Bosch’s expertise in MEMS manufacturing and ensure high-volume capacity for fast growing markets such as 5G, IoT, and automotive.

- »5G will be a Game Changer for MEMS Oscillators«

- Emerald Platform for 5G